Nov . 11, 2024 12:53 Back to list

auto lift power unit product

Understanding Auto Lift Power Units Enhancing Automotive Service Efficiency

In the automotive service industry, efficiency and reliability are critical components that directly impact a business's success. One of the most significant innovations that have contributed to this enhancement is the auto lift power unit. This essential piece of equipment enables mechanics to perform repairs and maintenance tasks more conveniently and safely, making it an indispensable asset in any automobile repair shop.

What is an Auto Lift Power Unit?

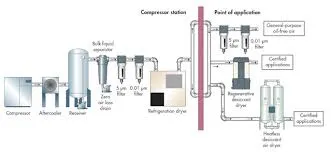

An auto lift power unit is a hydraulic system designed to raise and lower vehicles using a lifting mechanism. These units are integral to various types of auto lifts, including two-post lifts, four-post lifts, and scissor lifts. The power unit serves as the driving force behind the lifting action, utilizing hydraulic fluid to create the necessary pressure for lifting heavy vehicles with minimal manual effort. Most modern units are equipped with electric motors and hydraulic pumps that ensure reliable and efficient operation.

Key Features of Auto Lift Power Units

1. Hydraulic Efficiency The most notable feature of an auto lift power unit is its hydraulic efficiency. It uses the principles of hydraulics to convert a small amount of manual force into a much larger lifting force. This makes auto lifts capable of raising vehicles weighing thousands of pounds with ease.

2. Safety Mechanisms Safety is paramount when working with heavy vehicles. Most power units come with built-in safety features such as automatic locks and emergency stops, which prevent accidents and equipment failure. These safety mechanisms ensure that vehicles remain securely elevated during service operations.

3. Compatibility and Versatility Auto lift power units are designed to be compatible with various types of lifts and vehicles. Whether it’s a compact car or a heavy-duty truck, the right power unit can accommodate a range of applications. This versatility makes them a valuable addition to any workshop, allowing service providers to handle diverse automotive tasks efficiently.

auto lift power unit product

4. Maintenance Requirements Regular maintenance is crucial to the longevity and performance of an auto lift power unit. Most units require periodic inspections, fluid changes, and troubleshooting for potential hydraulic leaks. Keeping the unit in optimal condition not only enhances safety but also ensures continuous high performance.

Benefits of Using Auto Lift Power Units

1. Increased Productivity By automating the lifting process, auto lift power units significantly reduce the time mechanics spend lifting and positioning vehicles. This increased productivity allows workshops to handle more vehicles, improving overall service output.

2. Improved Working Conditions Lifting vehicles manually is not only time-consuming but also poses physical risks to workers. Auto lift power units alleviate these risks by minimizing manual labor, thereby creating a safer working environment.

3. Enhanced Accuracy With an auto lift power unit, mechanics can achieve a precise lift height, allowing for better access to various vehicle components. This accuracy in vehicle positioning leads to improved repair quality and customer satisfaction.

4. Cost-Effectiveness Although there is an upfront investment required for auto lift power units, the long-term savings are substantial. With increased productivity and reduced injury claims, repair shops can expect a strong return on investment over their operational lifespan.

Conclusion

In the realm of vehicle service and repair, auto lift power units are a game-changer. Their ability to lift heavy vehicles safely and efficiently not only improves productivity but also enhances the overall working conditions for mechanics. For any automotive service provider looking to streamline operations and improve service quality, investing in a high-quality auto lift power unit is a wise decision. As technology continues to evolve, we can expect even more innovations in hydraulic engineering, further increasing the capabilities and reliability of these essential tools in the automotive industry.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025