Dec . 12, 2024 12:10 Back to list

auto lift power unit factories

The Evolution of Auto Lift Power Unit Factories

The automotive industry has consistently been at the forefront of technological advancements, driving improvements in efficiency, safety, and precision. A critical component of this evolution is the auto lift power unit, which plays a pivotal role in the functionality and reliability of automotive service equipment. The factories producing these power units have undergone significant transformations to keep pace with the industry's demands, focusing on innovation, sustainability, and quality.

Understanding Auto Lift Power Units

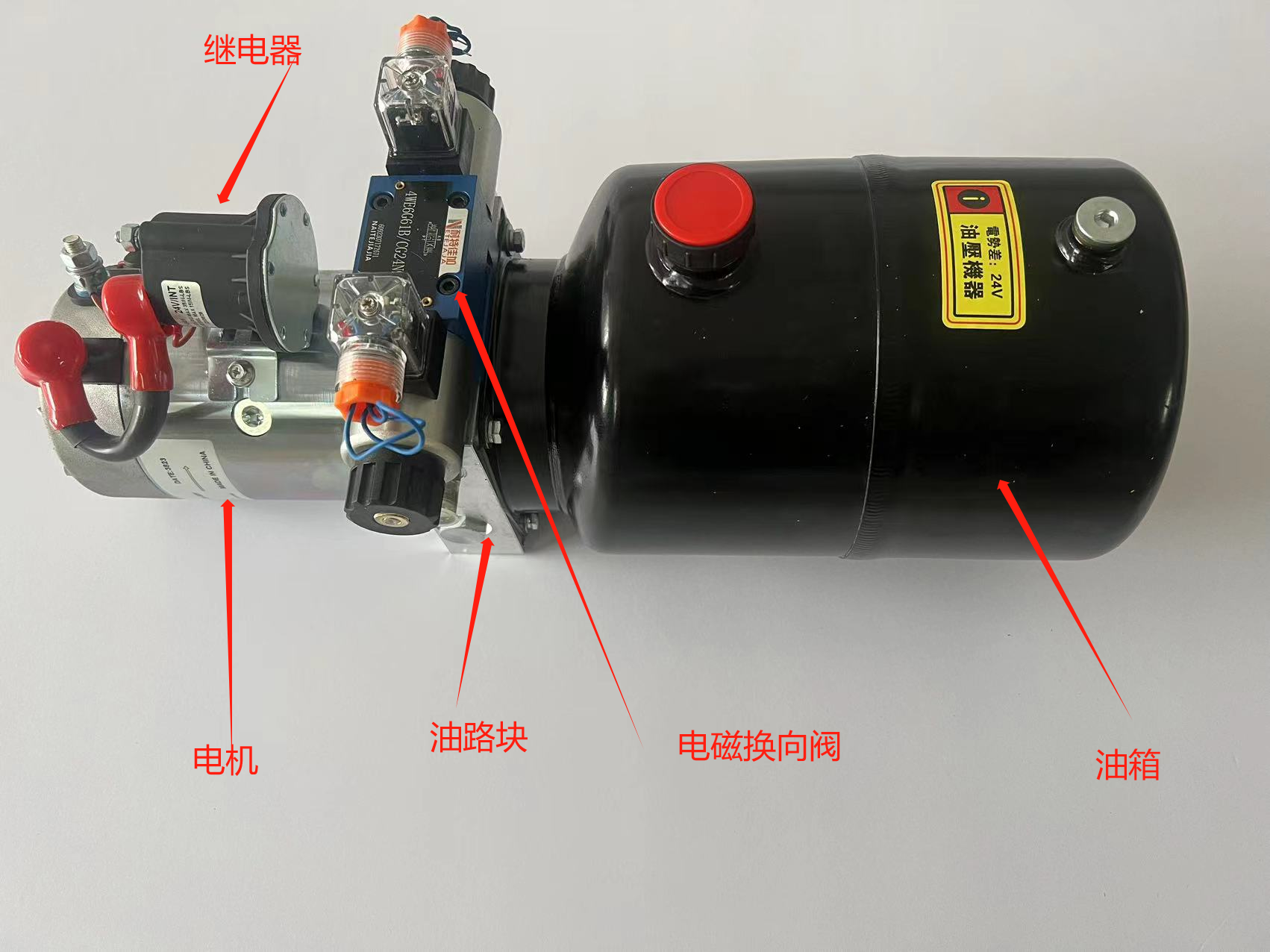

Auto lift power units are essential for the operation of vehicle lifting systems found in garages, service stations, and manufacturing plants. These power units typically consist of hydraulic systems that raise and lower vehicles for maintenance, repair, or inspection. As the complexity of vehicles increases, so too does the requirement for more sophisticated lifting equipment. This shift has driven factories to innovate and optimize their production processes.

Historical Context

Historically, auto lift power units were relatively simple devices powered by hydraulic pumps, primarily driven by electric motors. However, as vehicles became heavier and more cumbersome, the power units needed to evolve. Manufacturers began integrating advanced technologies such as electronic control systems, load sensors, and automatic safety features, requiring changes in factory operations and design philosophies.

Current Manufacturing Trends

Modern auto lift power unit factories are now equipped with state-of-the-art technology that enhances both productivity and quality. Automation has become a hallmark of these facilities, allowing for increased precision in manufacturing and reduced labor costs. Robotics and computer numerical control (CNC) machines streamline the production of components, ensuring consistency and efficiency.

auto lift power unit factories

Additionally, modern manufacturing practices are increasingly focusing on sustainability. Many factories are adopting eco-friendly practices, such as recycling waste materials, utilizing energy-efficient machinery, and minimizing emissions. This shift not only helps the environment but also meets the growing consumer demand for greener products.

The Role of Quality Control

Quality control remains a cornerstone in the production of auto lift power units. With the high stakes involved in automotive safety, manufacturers employ rigorous testing protocols to ensure that every unit meets industry standards. This includes pressure tests, endurance tests, and performance assessments. Factories are also increasingly leveraging data analytics and IoT devices to monitor machinery performance, further enhancing their quality assurance processes.

Future Prospects

Looking ahead, the future of auto lift power unit factories seems promising. The ongoing evolution of electric and hybrid vehicle technologies necessitates the development of new lifting systems that cater to their unique requirements. Additionally, the rise of electric vehicles has already begun to influence power unit design, as these vehicles often require specialized lifting solutions.

Moreover, as the industry shifts towards greater automation and smart technologies, auto lift power units will likely incorporate features such as wireless connectivity and real-time diagnostics. This evolution will not only enhance the functionality of the lifts but also improve the efficiency of automotive service operations.

Conclusion

Auto lift power unit factories are at a critical juncture, adapting to the rapid advancements in the automotive sector. By embracing innovation, prioritizing quality, and implementing sustainable practices, these factories are well-positioned to meet the evolving needs of the industry. As we look to the future, the potential for cutting-edge technologies and smarter manufacturing processes will continue to shape the landscape of auto lift power unit production, ensuring that safety, efficiency, and performance remain at the forefront of automotive service. The journey is not just about lifting vehicles; it is about elevating the standards of the automotive industry itself.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025