Oct . 09, 2024 07:42 Back to list

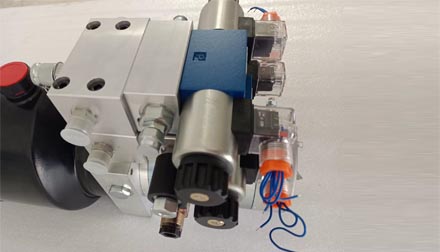

air hydraulic cylinder product

The Versatility and Applications of Air Hydraulic Cylinders

Air hydraulic cylinders are essential components in various industrial applications, providing a blend of air and hydraulic power to perform heavy lifting and pushing tasks efficiently. These cylinders harness the power of compressed air to exert a significant force through hydraulic fluid, making them powerful tools for a multitude of applications across diverse sectors, including manufacturing, automotive, construction, and more.

Understanding Air Hydraulic Cylinders

An air hydraulic cylinder operates on a relatively straightforward principle. Compressed air is used to push hydraulic fluid, which then exerts a force on a piston. This mechanism allows for precise control of high force output relative to the cylinder's size. The major components of an air hydraulic cylinder include the air supply system, the hydraulic circuit, and the cylinder itself, which houses the piston. Often, operators can adjust the air pressure to regulate the hydraulic system's output, making these cylinders exceptionally versatile.

Advantages of Air Hydraulic Cylinders

1. High Force Output One of the greatest advantages of air hydraulic cylinders is their ability to generate large amounts of force. This makes them suitable for pushing, pulling, lifting, and holding heavy loads.

2. Control and Precision Operators can finely control the speed and position of the cylinder through the adjustment of air pressure and hydraulic flow. This is particularly useful in applications where precision is paramount.

3. Reduced Weight Compared to traditional hydraulic cylinders, air hydraulic cylinders tend to be lighter. This increased portability can significantly enhance workflow efficiency, especially in environments where equipment needs to be moved frequently.

4. Energy Efficient Using compressed air can lead to increased efficiency in certain applications, as it often uses less energy than traditional hydraulic systems. Air hydraulic systems can be integrated into existing setups with minimal energy waste.

5. Safety Features Many air hydraulic cylinders come equipped with safety features like pressure relief valves and locking mechanisms. These features help prevent accidental release or failure, contributing to a safer work environment.

Applications Across Industries

The impact of air hydraulic cylinders can be seen across various industries

air hydraulic cylinder product

- Manufacturing In assembly lines, air hydraulic cylinders are often used for tasks such as lifting equipment, positioning heavy machinery, and pushing components into place. Their ability to exert substantial force while allowing for precise movements makes them ideal for these applications.

- Automotive In the automotive industry, air hydraulic cylinders play a crucial role in lifting vehicles for inspection or maintenance. They are also used in tools designed for repairs and assembly, helping to streamline production processes.

- Construction Air hydraulic cylinders are used in construction equipment for tasks like drilling, lifting, and compacting materials. This use enhances productivity by enabling workers to accomplish heavier tasks with less physical effort.

- Material Handling Warehousing and logistics sectors utilize air hydraulic cylinders for conveyor systems, loading docks, and automated material handling systems. Their efficiency and effectiveness in handling heavy loads improve overall operations.

Considerations for Choosing Air Hydraulic Cylinders

When selecting an air hydraulic cylinder for a specific application, several factors should be considered

- Load Capacity Ensure the cylinder can handle the maximum force required for the task at hand. - Stroke Length Determining the required stroke length is vital to ensure that the cylinder can perform its intended function without limitations.

- Environmental Conditions Consider the working environment. Cylinders may need to be resistant to dust, moisture, or extreme temperatures depending on the application.

- Air Supply Assess whether your current air supply system is sufficient to meet the cylinder's operational needs.

Conclusion

Air hydraulic cylinders represent an efficient, powerful, and versatile choice for various industrial applications. With their ability to combine the best features of air and hydraulic systems, they not only enhance productivity but also improve safety in numerous environments. As industries continue to evolve and demand greater efficiency, the role of air hydraulic cylinders is likely to expand, solidifying their place as a cornerstone of modern engineering and manufacturing practices. Whether you're in manufacturing, automotive, or construction, embracing this technology could significantly enhance your operational efficiency and effectiveness.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025