Aug . 13, 2024 09:34 Back to list

Affordable Hydraulic Cylinder Price Comparison from Leading Manufacturers and Factories Worldwide

Understanding Hydraulic Cylinder Prices A Comprehensive Overview

Hydraulic cylinders are essential components in various industrial applications, serving as mechanisms that convert hydraulic energy into mechanical force. They are utilized in construction equipment, automotive machinery, manufacturing processes, and more. As demand for hydraulic cylinders continues to grow, understanding their pricing and the factors that influence it becomes increasingly important for businesses and consumers alike. In this article, we will explore the key factors that affect hydraulic cylinder prices and provide insights into how to navigate this market effectively.

Factors Influencing Hydraulic Cylinder Prices

1. Raw Materials The primary materials used in manufacturing hydraulic cylinders include steel, aluminum, and various seals and gaskets. Fluctuations in the prices of these raw materials can significantly affect the final cost of the cylinders. For instance, a rise in steel prices due to market demand or geopolitical issues can lead to increased manufacturing costs, which are then passed on to consumers.

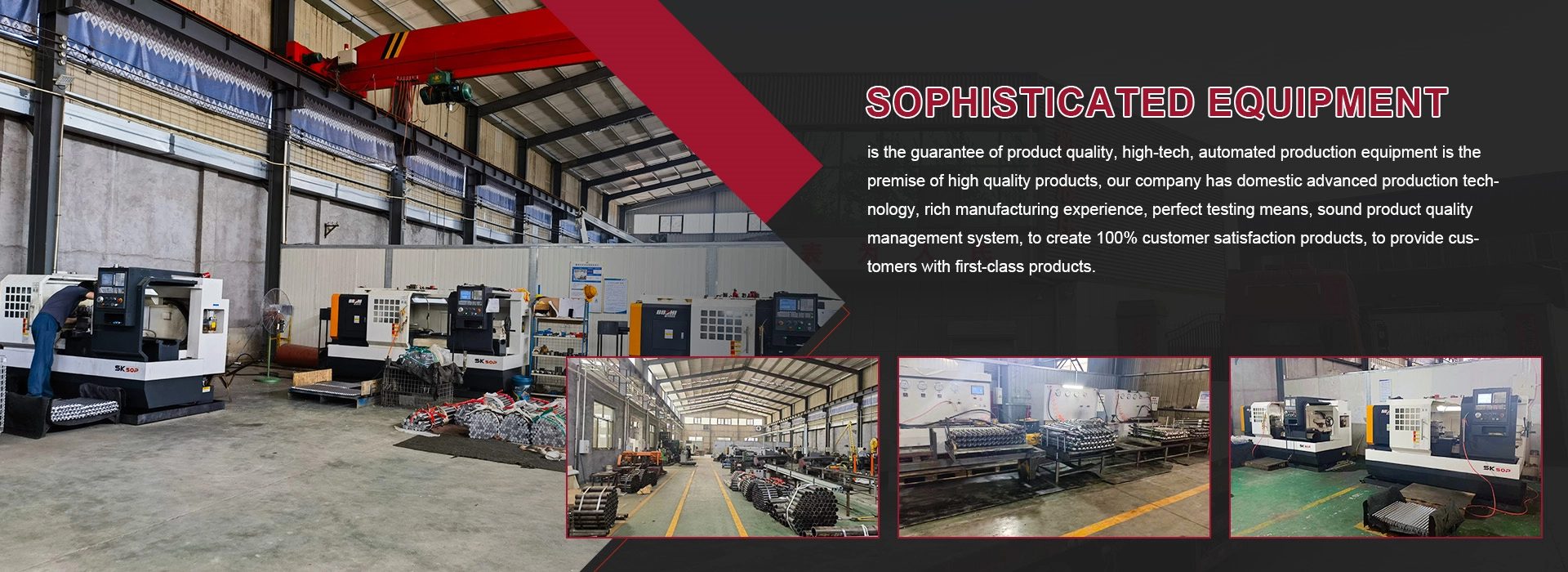

2. Manufacturing Processes The complexity of the manufacturing process also plays a critical role in determining hydraulic cylinder prices. High-quality cylinders often undergo advanced manufacturing techniques, such as precision machining, heat treatment, and surface coating, to enhance their durability and performance. These processes require specialized equipment and skilled labor, contributing to higher production costs.

3. Specifications and Customization Standard hydraulic cylinders are typically less expensive than custom-built models. Businesses requiring specific dimensions, materials, or performance characteristics should expect to pay a premium for customization. Additionally, the complexity of the design, such as multi-stage cylinders or those with additional features (like sensors), can further increase the price.

4. Brand Reputation Established manufacturers with a reputation for quality often charge higher prices for their products. Such brands invest in research and development, rigorous testing, and customer service, ensuring that their hydraulic cylinders meet stringent quality standards. For buyers, these factors can justify the higher price tag, particularly when reliability and performance are critical.

5. Market Demand The market demand for hydraulic cylinders can fluctuate due to various factors, including economic conditions, technological advancements, and trends in related industries. For example, an increase in construction projects or automotive manufacturing can lead to higher demand for hydraulic systems, driving up prices. Conversely, economic downturns may reduce demand and lead to lower prices.

hydraulic cylinder price factory

6. Geographic Location The location of both the manufacturer and the buyer can influence prices. Shipping costs, import duties, and local market conditions can all impact the final price of a hydraulic cylinder. Buyers in regions with high shipping costs may find that prices are significantly higher than those in areas closer to manufacturing facilities.

Navigating the Hydraulic Cylinder Market

For businesses looking to purchase hydraulic cylinders, understanding the factors that influence pricing can help in making informed decisions. Here are some tips for navigating the market effectively

- Conduct Market Research Before making a purchase, compare prices from different manufacturers and suppliers. Consider the specifications required for your application and weigh the costs against quality and reliability.

- Evaluate Long-term Value While it may be tempting to opt for the cheapest option, consider the long-term value of investing in high-quality hydraulic cylinders. Improved durability and performance can lead to lower maintenance costs and increased productivity over time.

- Seek Expert Advice Consulting with industry experts can provide valuable insights into the best options for your specific needs. They can help identify reputable suppliers and highlight potential pitfalls.

In conclusion, the price of hydraulic cylinders is influenced by a myriad of factors ranging from raw material costs to market demand. By understanding these elements and conducting thorough research, businesses can make informed decisions that align with their operational needs and budget constraints.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025