Oct . 19, 2024 19:58 Back to list

2 stage telescopic hydraulic cylinder products

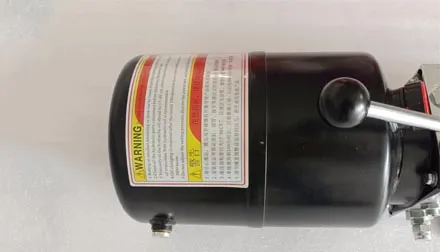

Understanding 2-Stage Telescopic Hydraulic Cylinders Features, Applications, and Benefits

Hydraulic cylinders play a crucial role in various industrial applications by converting hydraulic energy into mechanical energy. Among these, the 2-stage telescopic hydraulic cylinder stands out due to its efficient design and ability to handle heavy loads. This article delves into the essential features, applications, and benefits of 2-stage telescopic hydraulic cylinders, offering insights into why they are a preferred choice in many industries.

What is a 2-Stage Telescopic Hydraulic Cylinder?

A 2-stage telescopic hydraulic cylinder consists of two or more nested cylinders that extend and retract to produce a considerable stroke length with a compact retracted length. The initial stage, or the first cylinder, extends to a certain length before the second stage activates, allowing for a significant increase in extension without requiring excessive space. This design makes it ideal for applications where space is limited yet the need for reach and force is paramount.

Key Features of 2-Stage Telescopic Hydraulic Cylinders

1. Compact Design One of the most significant advantages of these cylinders is their compact size when retracted. This is particularly useful in machinery where space is limited.

2. High Load Capacity 2-stage telescopic hydraulic cylinders can handle substantial loads, making them suitable for heavy-duty applications.

3. Variable Stroke Lengths The use of multiple stages allows for varying stroke lengths depending on the requirements of the application.

4. Efficiency The design maximizes the force output while minimizing hydraulic fluid consumption, leading to greater energy efficiency.

5. Robust Construction Typically made from high-strength materials, these cylinders are built to endure harsh working conditions and have a long service life.

Applications of 2-Stage Telescopic Hydraulic Cylinders

The versatility of 2-stage telescopic hydraulic cylinders has led to their widespread use across multiple industries, including

2 stage telescopic hydraulic cylinder products

1. Construction These cylinders are commonly used in construction equipment like excavators, cranes, and forklifts. They allow for the lifting and moving of heavy materials over considerable distances.

2. Mining In mining operations, these cylinders help in tasks like lifting and extending machinery, providing the necessary reach and power.

3. Transport Trucks and trailers often employ telescopic hydraulic cylinders for loading and unloading cargo effectively.

4. Agriculture Agricultural machinery, such as loaders and tractors, utilizes these cylinders for various tasks, including lifting and dumping materials.

5. Manufacturing In manufacturing setups, these cylinders can be found in automation equipment, providing the necessary actuation force in assembly lines.

Benefits of 2-Stage Telescopic Hydraulic Cylinders

1. Space-Saving With their retractable design, they allow for extensive functionality in confined areas.

2. Cost-Effectiveness The efficiency and durability of telescopic cylinders often translate into lower operational and maintenance costs.

3. Improved Safety Due to their robust design and reliable operation, these cylinders contribute to safer work environments by minimizing the risk of equipment failure during critical tasks.

4. Enhanced Productivity The ability to lift and extend with a compact unit allows for faster operation cycles, enhancing overall productivity.

In conclusion, 2-stage telescopic hydraulic cylinders represent a significant innovation in hydraulic technology, offering a combination of compact design, high load capacity, and versatility across various applications. With their numerous advantages, these cylinders are essential in modern industry, contributing to efficiency and productivity while ensuring robust performance in demanding environments. Whether in construction, agriculture, mining, or manufacturing, the 2-stage telescopic hydraulic cylinder is undoubtedly a vital component in the machinery that drives global industries forward.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025