Oct . 31, 2024 23:18 Back to list

Hydraulic Clamping Cylinder Solutions for Enhanced Performance and Reliability in Industrial Applications

Hydraulic Clamping Cylinder An Overview

Hydraulic clamping cylinders are essential components in various industrial applications where precision and reliability are crucial. These cylinders utilize hydraulic power to create powerful clamping forces, making them ideal for operations such as metalworking, woodworking, and assembly processes. The hydraulic clamping cylinder is designed to provide consistent and effective clamping while maintaining ease of operation, ensuring that tasks are completed efficiently and safely.

Hydraulic Clamping Cylinder An Overview

One of the primary advantages of hydraulic clamping cylinders is their ability to provide uniform clamping force across surfaces. This feature is particularly important in applications like machining or welding, where uneven or insufficient clamping can lead to inaccuracies and defects. By ensuring that the workpiece is securely held in place, these cylinders enhance the reliability of the manufacturing process and ultimately improve the quality of the final product.

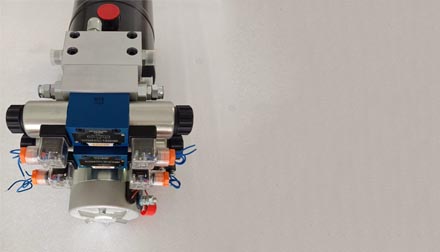

hydraulic clamping cylinder product

Additionally, hydraulic clamping cylinders are known for their versatility. They can be configured in various sizes and designs to suit different applications and specifications. Whether used in large-scale manufacturing or in small workshops, there is a hydraulic clamping cylinder that can meet the requirements of the task at hand. Some models even offer adjustable clamping force, allowing operators to customize the pressure applied depending on the material and job specifications.

Another significant feature is the quick-release capability of these cylinders. Many hydraulic clamping systems are designed to enable swift disengagement, which minimizes downtime during production. This is particularly beneficial in environments that require frequent loading and unloading of workpieces. The quick-release action ensures that operations can be completed without unnecessary delays, leading to improved productivity.

Moreover, maintenance and safety are vital considerations in the use of hydraulic clamping cylinders. Modern designs often include safety features such as pressure relief valves to prevent over-pressurization, which could lead to cylinder failure. Regular maintenance is also essential to ensure the longevity of the cylinders and the safety of their operation. By adhering to recommended service intervals and checking for leaks or wear, operators can effectively prolong the life of hydraulic clamping cylinders.

In conclusion, hydraulic clamping cylinders play an indispensable role in modern manufacturing and assembly processes. Their ability to deliver powerful, consistent, and adjustable clamping forces enhances productivity and product quality while ensuring operational safety. As technology continues to evolve, innovations in hydraulic systems are likely to further improve the efficiency and effectiveness of clamping solutions across various industries.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Precision Engineering&Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solution, Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd. | High Performance, Durable, Industrial Use

NewsJul.21,2025