ऑगस्ट . 20, 2024 23:52 Back to list

Custom Hydraulic Cylinders for Press Applications with Tailored Solutions and High Performance

Custom Shop Press Hydraulic Cylinder A Comprehensive Overview

In today's world of advanced machinery and engineering, the role of hydraulic systems has become increasingly significant, especially in custom workshops and manufacturing environments. Among the most important components of these hydraulic systems are hydraulic cylinders. The custom shop press hydraulic cylinder is a pivotal element that caters to the needs of various industrial applications, providing the necessary power and precision to perform tasks that other systems may struggle to accomplish.

Hydraulic cylinders convert hydraulic energy into mechanical energy, enabling the execution of heavy-duty tasks. These cylinders are composed of a cylindrical barrel, a piston system, and rods. When hydraulic fluid is pumped into the cylinder, the pressure exerted upon the piston generates linear force, which can then be harnessed to move, lift, or crush materials. Custom hydraulic cylinders are tailored to meet specific requirements, allowing businesses to maximize efficiency in their operations.

One of the foremost benefits of utilizing custom shop press hydraulic cylinders is their adaptability. In industries ranging from metalworking and automotive to construction and woodworking, the capacity to design cylinders that accommodate particular pressures, sizes, and functionalities is crucial. For instance, a manufacturer may require a hydraulic cylinder that can exert a force of 10,000 pounds to shape or mold materials. By customizing the cylinder's specifications, the manufacturer can ensure that their press performs optimally, leading to better product quality and reduced wear on machinery.

Moreover, the ability to customize shop press hydraulic cylinders also contributes to safety. Ensuring that hydraulic systems operate within their designed pressure limits is critical to preventing accidents in the workplace. Custom cylinders can be engineered with safety features such as pressure relief valves and over-pressure protection systems. These enhancements safeguard both personnel and equipment, minimizing the risks associated with hydraulic failures.

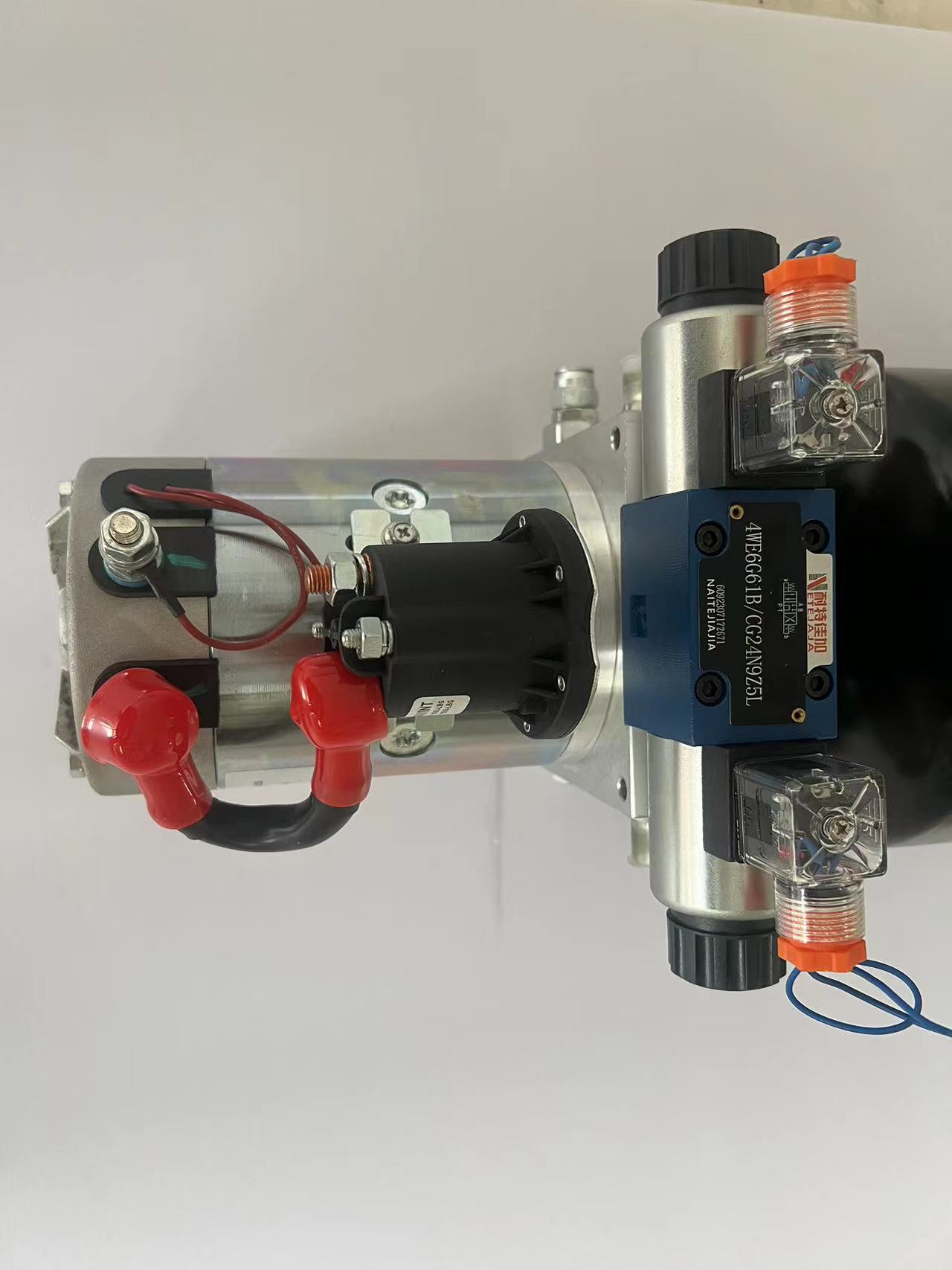

custom shop press hydraulic cylinder

Another notable advantage is the efficiency of operations. Custom hydraulic cylinders can significantly enhance production timelines. For example, if a business needs to perform repetitive tasks, such as stamping metal parts, a tailored hydraulic press can execute these operations more quickly and with greater precision than standardized equipment. Additionally, companies can integrate automation into these systems, optimizing workflows and further improving productivity.

Cost-effectiveness is another critical aspect of custom hydraulic cylinders. While the initial investment in customized equipment may seem high, the long-term savings often outweigh these costs. Customized hydraulic cylinders that improve productivity and reduce downtime ultimately lead to decreased operational expenses. Furthermore, they can lower maintenance costs since a well-designed hydraulic cylinder typically experiences fewer breakdowns and malfunctions.

When looking to invest in custom shop press hydraulic cylinders, it is essential to choose a reputable manufacturer. Companies should consider factors such as experience, customer reviews, and the ability to provide ongoing technical support. Collaborating with experts in the field can help businesses identify the best materials and designs suited for their specific applications.

In conclusion, custom shop press hydraulic cylinders play a vital role in enhancing industrial productivity and ensuring operational safety. Their adaptability, efficiency, and cost-effectiveness make them indispensable tools in various sectors. As technology advances, the design and functionality of hydraulic cylinders will continue to evolve, further empowering industries to meet the challenges of an increasingly demanding marketplace. Investing in a custom hydraulic solution remains not only a strategic choice but a pathway to sustained growth and success in the competitive world of manufacturing.

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025