12-р сар . 01, 2024 23:44 Back to list

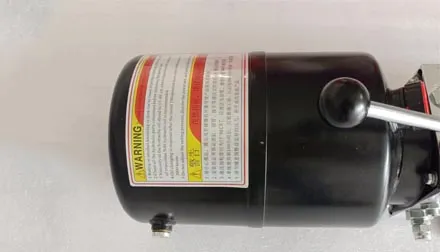

custom chief hydraulic cylinder

Understanding Custom Chief Hydraulic Cylinders Innovation in Design and Functionality

In the world of industrial machinery and mobile equipment, hydraulic systems are pivotal. Among the key components of these systems are hydraulic cylinders, which convert hydraulic energy into mechanical energy to perform various tasks. Custom chief hydraulic cylinders are at the forefront of this technology, providing tailored solutions that enhance performance, efficiency, and reliability across a wide range of applications.

What Are Hydraulic Cylinders?

Hydraulic cylinders are mechanical devices that use pressurized fluid to create linear motion and force. They consist of a cylindrical tube, a piston, and various seals and fittings. When hydraulic fluid is pumped into the cylinder, it pushes the piston, allowing the cylinder to extend or retract. This simple yet effective mechanism is utilized in various sectors, including construction, automotive, marine, and manufacturing.

The Importance of Customization

While standard hydraulic cylinders serve many purposes, there are instances where a one-size-fits-all approach is inadequate. This is where custom chief hydraulic cylinders come into play. Customization allows engineers and designers to develop cylinders that meet specific operational requirements and constraints. This can include modifications to dimensions, pressure ratings, mounting styles, and even material selection, ensuring that the cylinder performs optimally in its intended environment.

Applications of Custom Hydraulic Cylinders

Custom hydraulic cylinders are essential in numerous applications. In the construction industry, they are used in heavy machinery such as excavators, bulldozers, and cranes. These machines require robust and reliable cylinders that can withstand extreme conditions while providing precise control. In the automotive sector, custom hydraulic cylinders are utilized in assembly lines, providing efficient and accurate movements for manufacturing processes.

Moreover, custom hydraulic cylinders are vital in agricultural equipment, where they play a role in lifting, tilting, and adjusting various implements. In the marine sector, these cylinders facilitate the operation of various components, including stabilizers and steering gear, ensuring smooth and safe navigation.

custom chief hydraulic cylinder

Advantages of Custom Chief Hydraulic Cylinders

1. Tailored Performance Custom cylinders are designed to meet the specific needs of a project, ensuring that they deliver exceptional performance. Engineers can specify the necessary stroke length, diameter, and pressure capacity, leading to improved efficiency and productivity.

2. Enhanced Durability Custom chief hydraulic cylinders can be built with materials and coatings that enhance their resistance to wear, corrosion, and extreme temperatures. This longevity reduces maintenance costs and downtime, providing a reliable solution for demanding applications.

3. Optimized Space Utilization In many cases, space constraints require specially designed hydraulic cylinders. Custom solutions can maximize the available space, allowing for more compact machinery without compromising performance.

4. Energy Efficiency Custom hydraulic cylinders can be designed to operate more efficiently, reducing energy consumption and lowering operational costs. Properly matched cylinder sizes and specifications contribute significantly to system performance.

5. Innovative Features Custom designs can incorporate advanced features such as integrated sensors or customized mounting options. This adds value by enhancing functionality and providing greater control over operations.

Conclusion

Custom chief hydraulic cylinders represent a significant advancement in hydraulic technology, offering tailored solutions that cater to specific operational demands across various industries. Their ability to enhance performance, durability, and efficiency makes them indispensable in today's technologically-driven world. As industries continue to evolve and require more specialized equipment, the demand for custom hydraulic cylinders will undoubtedly grow, solidifying their importance in the future of mechanical and hydraulic engineering. By choosing custom solutions, companies can ensure they remain competitive, efficient, and prepared for the challenges of tomorrow.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan | Heavy-Duty Hydraulic Solutions

NewsJul.29,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Heavy-Duty Hydraulic Solutions&Precision Engineering

NewsJul.29,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Precision Engineering&Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solution, Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025