Јул . 22, 2024 02:47 Back to list

Exploring the Performance and Efficiency of Cylinder Hydraulic Pumps for Various Applications

The Importance of Cylinder Hydraulic Pumps in Modern Machinery

Hydraulic pumps play a pivotal role in mechanical systems, particularly in the operation of heavy machinery and equipment. Among the various types of hydraulic pumps, cylinder hydraulic pumps stand out for their efficiency, reliability, and versatility. These pumps convert mechanical energy into hydraulic energy, providing the necessary force to power hydraulic systems in various applications, from construction equipment to manufacturing processes.

What is a Cylinder Hydraulic Pump?

A cylinder hydraulic pump is a device that uses the movement of pistons or cylinders to generate hydraulic pressure. Inside the pump, fluids are drawn into the cylinders, where mechanical force compresses them, thereby elevating their pressure. These pumps can be either single-acting or double-acting, depending on whether the hydraulic fluid is pressurized on one or both sides of the piston. This mechanism allows cylinder hydraulic pumps to handle substantial loads while maintaining a compact design.

Applications in Industries

Cylinder hydraulic pumps are integral to numerous industries. In construction, for instance, they are employed in excavators, bulldozers, and cranes, enabling them to lift heavy loads and perform intricate maneuvers. In manufacturing, these pumps assist in operating presses, conveyors, and hydraulic tools, enhancing productivity and precision in production lines. The automotive industry also relies on these pumps for assembly lines, where they facilitate the efficient operation of robotic arms and other automation equipment.

Advantages of Cylinder Hydraulic Pumps

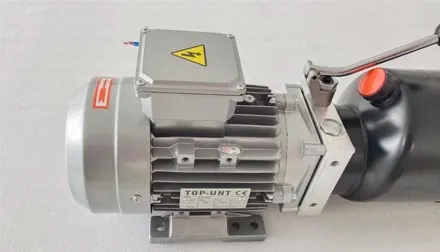

cylinder hydraulic pump product

One of the key benefits of cylinder hydraulic pumps is their ability to produce a high amount of force relative to their size, which makes them ideal for heavy-duty applications. The hydraulic system also provides smooth and controlled movements, making it easier to manipulate large objects with precision. Additionally, cylinder hydraulic pumps are known for their durability and longevity. With proper maintenance, they can operate efficiently for years, reducing the need for frequent replacements.

Another significant advantage is the ease of control they offer. Operators can easily adjust the flow and pressure of the hydraulic fluid, allowing for fine-tuning of the system’s performance. This flexibility is crucial in applications that require specific movements or force, enabling operators to achieve optimal results with minimal effort.

Maintenance and Considerations

While cylinder hydraulic pumps are robust, regular maintenance is essential to ensure their longevity and efficiency. Users must check for leaks, monitor fluid levels, and inspect the components for wear and tear. Implementing a preventative maintenance schedule can help identify issues before they become severe, ultimately saving time and reducing repair costs.

When selecting a cylinder hydraulic pump for a specific application, several factors must be considered, including the pump's capacity, pressure rating, and compatibility with the hydraulic system. It is crucial to match the pump's specifications with the operational demands to ensure optimal performance.

Conclusion

In conclusion, cylinder hydraulic pumps are vital components in a variety of industries, providing the power and precision necessary to drive hydraulic systems. Their high efficiency, compact size, and ease of control make them indispensable in the realm of heavy machinery and automotive manufacturing. As industries continue to evolve, the demand for reliable and effective hydraulic solutions, like cylinder hydraulic pumps, will only increase, solidifying their role as a cornerstone of modern engineering and machinery.

-

Custom-Built 2-Post Lift Power Units High-Performance Hydraulic Systems

NewsJun.01,2025

-

High-Performance Hydraulic Damping Cylinders Manufacturer Superior Power

NewsJun.01,2025

-

Custom Dual Loader Hydraulic Cylinders Manufacturer Durable Solutions

NewsMay.31,2025

-

Custom Ladder Rack Hydraulic Cylinders Heavy-Duty & Tailored Solutions

NewsMay.31,2025

-

Tilt Bed Trailer Hydraulic Cylinder Factories Heavy-Duty Custom Solutions

NewsMay.31,2025

-

Premium Car Tailgate Power Units Reliable OEM Solutions

NewsMay.31,2025