Mar . 07, 2025 05:53 Back to list

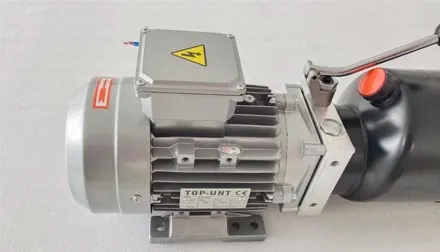

Double acting power units

A custom double acting hollow hydraulic cylinder is a high-performance component fundamental to many industrial and engineering applications. Its versatile design and robust functionality provide unique advantages that cater to a range of sectors, from manufacturing and construction to mining and aerospace. Understanding the nuanced benefits and applications of this type of cylinder enhances the decision-making process for professionals seeking to optimize their operational efficacy.

Trustworthiness is built through a transparent supply chain and robust customer support. Companies offer extensive warranties and readily available technical guidance to foster client confidence in using these complex components. By facilitating a dialogue between engineers and end-users, they ensure that each custom cylinder is integrated seamlessly into its respective system, thereby enhancing operational reliability. Industries employing these cylinders benefit broadly from their adaptability and efficiency. In the construction sector, they are pivotal in heavy machinery such as excavators and cranes, where robust load-bearing capabilities and precise control are paramount. Aerospace applications rely on these cylinders for actuation systems where precision and weight considerations are critical. In manufacturing, customized hydraulic cylinders contribute to automation and robotics, enhancing speed and accuracy in production lines. Furthermore, double acting hollow design offers a lighter option compared to solid pistons, which is crucial in applications where weight reduction translates to increased efficiency or safety. The hollow rod also allows the integration of components such as sensors within the cylinder, offering feedback and control mechanisms that align with modern Industry 4.0 standards. This adaptability makes them suitable for integration with smart systems, advancing capabilities in predictive maintenance and autonomous operation. In conclusion, custom double acting hollow hydraulic cylinders represent an intersection of expertise, authority, and trust within the hydraulic industry. They empower sectors demanding precision and endurance, offering bespoke solutions that address unique operational challenges. Their role in advancing industrial efficiency and reliability underscores their growing indispensability in modern engineering applications.

Trustworthiness is built through a transparent supply chain and robust customer support. Companies offer extensive warranties and readily available technical guidance to foster client confidence in using these complex components. By facilitating a dialogue between engineers and end-users, they ensure that each custom cylinder is integrated seamlessly into its respective system, thereby enhancing operational reliability. Industries employing these cylinders benefit broadly from their adaptability and efficiency. In the construction sector, they are pivotal in heavy machinery such as excavators and cranes, where robust load-bearing capabilities and precise control are paramount. Aerospace applications rely on these cylinders for actuation systems where precision and weight considerations are critical. In manufacturing, customized hydraulic cylinders contribute to automation and robotics, enhancing speed and accuracy in production lines. Furthermore, double acting hollow design offers a lighter option compared to solid pistons, which is crucial in applications where weight reduction translates to increased efficiency or safety. The hollow rod also allows the integration of components such as sensors within the cylinder, offering feedback and control mechanisms that align with modern Industry 4.0 standards. This adaptability makes them suitable for integration with smart systems, advancing capabilities in predictive maintenance and autonomous operation. In conclusion, custom double acting hollow hydraulic cylinders represent an intersection of expertise, authority, and trust within the hydraulic industry. They empower sectors demanding precision and endurance, offering bespoke solutions that address unique operational challenges. Their role in advancing industrial efficiency and reliability underscores their growing indispensability in modern engineering applications.

Next:

Latest news

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025