Jan . 28, 2025 01:37 Back to list

high quality cross section of hydraulic cylinder

Exploring the High-Quality Cross Section of Hydraulic Cylinders An In-Depth Analysis for Optimized Efficiency and Durability

Seal Technology Enhancing Performance and Longevity Seals are the unsung heroes within a hydraulic cylinder's cross section. Their function is to retain hydraulic fluid and prevent contaminant ingress, safeguarding the overall integrity of the cylinder. A significant innovation in seal technology is the advent of composite materials and refined profiles, which provide superior adaptability and resistance to dynamic pressures. By leveraging expertise in polymer science, manufacturers develop seals that align perfectly with the cylinder’s geometry, reinforcing the premise that excellence in cross section design directly correlates to enhanced seal performance. Consistent research and development ensure that hydraulic seals remain robust across varying temperatures and environmental challenges. Quality Assurance and Testing Establishing Trust in Hydraulic Products Authoritativeness in hydraulic cylinder manufacturing stems from rigorous quality assurance protocols. Adopting a comprehensive testing regime that encompasses pressure tests, fatigue assessments, and thermal stress analysis is imperative. Such evaluations not only authenticate the reliability of each cylinder but also foster trust within the marketplace. Moreover, certification from industry-recognized bodies serves as a testament to a manufacturer’s commitment to quality. Adhering to international standards like ISO 6020/2 or ISO 3320 provides customers with assurance, reinforcing that the hydraulic cylinders are fit for purpose across a multitude of industrial applications. Customer Experience Adapting Insights for Tailored Solutions Each industrial sector presents unique demands; hence the ability to customize cylinder cross sections based on specific application requirements is invaluable. Expert consultation services should be available to guide clients through the intricacies of cylinder selection and integration into existing systems. The expertise provided can encompass everything from bespoke design adjustments to after-sales support, ensuring that the user experience remains at the forefront. In conclusion, the pursuit of excellence in hydraulic cylinder cross section design is a testament to the technological advancements and expertise cultivated within the industry. By prioritizing high-quality materials, innovative engineering solutions, and unwavering quality standards, manufacturers can deliver hydraulic cylinders that set new benchmarks in performance and reliability. Such commitment not only strengthens brand authority but also deepens trust with each cylinder installed across industries worldwide.

Seal Technology Enhancing Performance and Longevity Seals are the unsung heroes within a hydraulic cylinder's cross section. Their function is to retain hydraulic fluid and prevent contaminant ingress, safeguarding the overall integrity of the cylinder. A significant innovation in seal technology is the advent of composite materials and refined profiles, which provide superior adaptability and resistance to dynamic pressures. By leveraging expertise in polymer science, manufacturers develop seals that align perfectly with the cylinder’s geometry, reinforcing the premise that excellence in cross section design directly correlates to enhanced seal performance. Consistent research and development ensure that hydraulic seals remain robust across varying temperatures and environmental challenges. Quality Assurance and Testing Establishing Trust in Hydraulic Products Authoritativeness in hydraulic cylinder manufacturing stems from rigorous quality assurance protocols. Adopting a comprehensive testing regime that encompasses pressure tests, fatigue assessments, and thermal stress analysis is imperative. Such evaluations not only authenticate the reliability of each cylinder but also foster trust within the marketplace. Moreover, certification from industry-recognized bodies serves as a testament to a manufacturer’s commitment to quality. Adhering to international standards like ISO 6020/2 or ISO 3320 provides customers with assurance, reinforcing that the hydraulic cylinders are fit for purpose across a multitude of industrial applications. Customer Experience Adapting Insights for Tailored Solutions Each industrial sector presents unique demands; hence the ability to customize cylinder cross sections based on specific application requirements is invaluable. Expert consultation services should be available to guide clients through the intricacies of cylinder selection and integration into existing systems. The expertise provided can encompass everything from bespoke design adjustments to after-sales support, ensuring that the user experience remains at the forefront. In conclusion, the pursuit of excellence in hydraulic cylinder cross section design is a testament to the technological advancements and expertise cultivated within the industry. By prioritizing high-quality materials, innovative engineering solutions, and unwavering quality standards, manufacturers can deliver hydraulic cylinders that set new benchmarks in performance and reliability. Such commitment not only strengthens brand authority but also deepens trust with each cylinder installed across industries worldwide.

Latest news

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

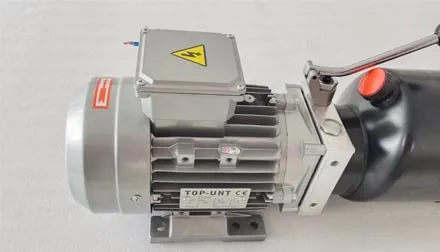

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025