ធ្នូ . 20, 2024 06:57 Back to list

skid steer hydraulic cylinder factory

Understanding Skid Steer Hydraulic Cylinders A Deep Dive into Factory Production

Skid steer loaders are a vital part of the construction, landscaping, and agriculture sectors. These compact machines are renowned for their versatility and efficiency, powered by a range of hydraulic systems. At the heart of these systems are hydraulic cylinders, which play a crucial role in the operation of skid steers. This article will explore the production processes involved in manufacturing these hydraulic cylinders in a factory setting, shedding light on the technology and precision required to produce reliable components.

The Role of Hydraulic Cylinders in Skid Steer Loaders

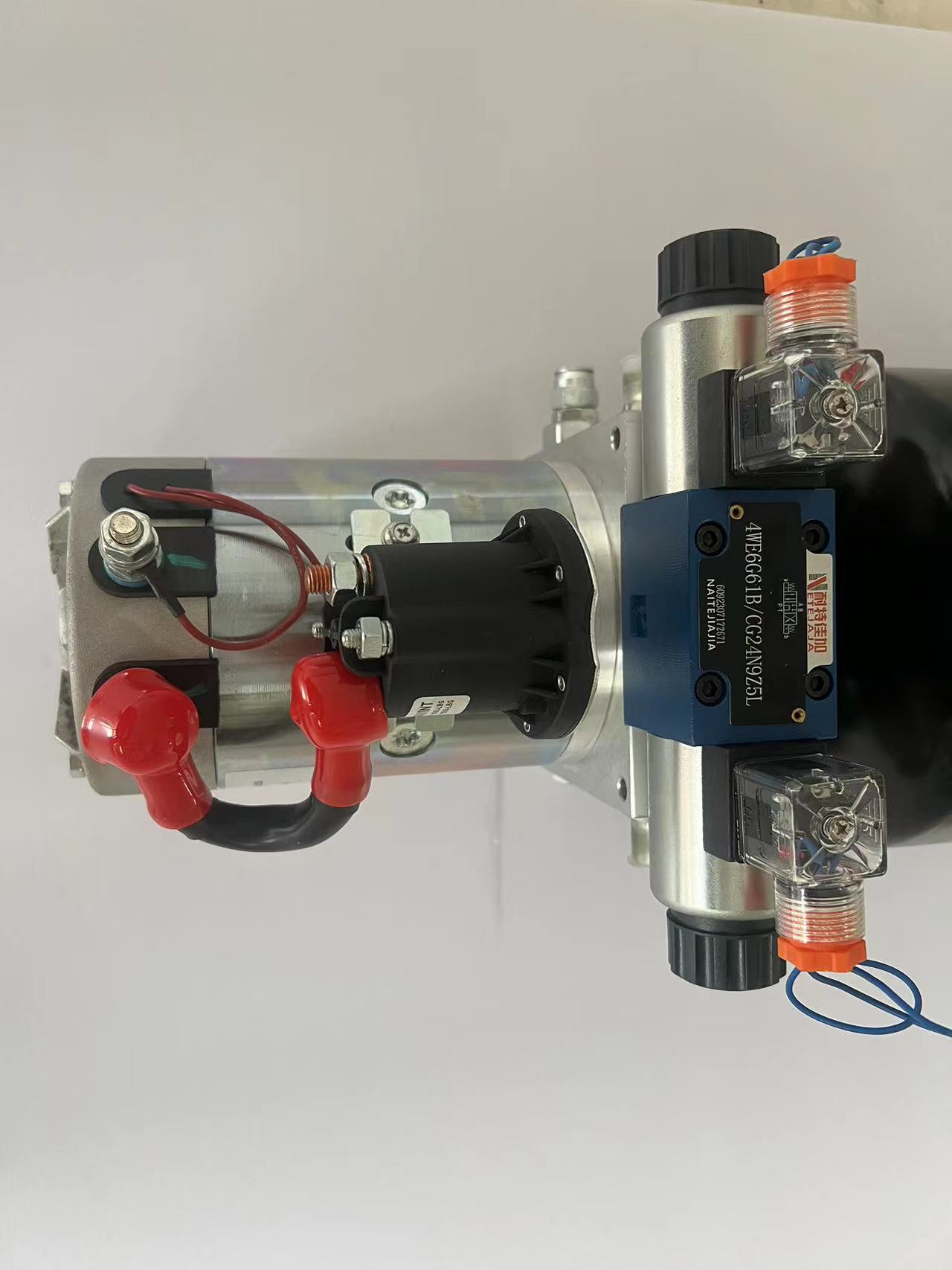

Hydraulic cylinders convert hydraulic energy into mechanical energy, enabling skid steer loaders to lift, push, and pull materials with ease. Essentially, these cylinders are operated by pressurized hydraulic fluid, which creates a force that moves a piston within the cylinder. This movement translates to the mechanical force needed to perform various tasks, such as lifting a bucket or tilting a loader attachment. The efficiency and reliability of a skid steer loader largely depend on the hydraulic cylinders' design and construction.

Factory Production Process of Hydraulic Cylinders

Producing hydraulic cylinders for skid steer loaders involves several critical stages, each requiring precise craftsmanship and quality control measures.

1. Material Selection Quality starts with selecting the right materials. Manufacturers typically use high-strength steel or aluminum to ensure durability and resistance to wear and corrosion. The choice of material affects the cylinder's weight, strength, and overall performance under heavy load conditions.

2. Machining Once materials are chosen, the raw materials undergo machining processes. This step includes cutting, boring, and grinding to achieve the required dimensions and surface finishes. Precision is paramount, as even minor deviations can lead to significant performance issues or hydraulic leaks.

skid steer hydraulic cylinder factory

3. Assembly of Components After machining, various components of the hydraulic cylinder, including the barrel, piston, and seals, are assembled. Using advanced automation and assembly techniques, manufacturers ensure that each component fits together perfectly. Attention to detail during this phase directly impacts the cylinder's performance and lifespan.

4. Quality Control Rigorous quality assurance tests are conducted throughout the manufacturing process. This includes non-destructive testing methods like ultrasonic testing and magnetic particle inspection to check for material integrity and any potential weak points. Additionally, cylinders undergo pressure testing to ensure they can handle the operational stress they will encounter in real-world applications.

5. Surface Treatment To enhance the corrosion resistance and prolong the life of hydraulic cylinders, surface treatments such as hard chrome plating or anodizing are frequently applied. These processes create a protective coating that not only defends against wear but also improves the aesthetic appeal of the finished product.

6. Final Inspection and Packing The final step in the manufacturing chain involves a thorough inspection of each hydraulic cylinder before packing. This ensures that only those meeting stringent quality standards are shipped to clients. Proper packaging is also essential to protect the cylinders during transportation, preventing any damage that could compromise their effectiveness.

Innovations in Hydraulic Cylinder Production

As technology evolves, so does the manufacturing process of hydraulic cylinders. Innovations such as computer-aided design (CAD) and computer numerical control (CNC) machining have significantly improved precision and efficiency in production. Moreover, the development of advanced materials and coatings has led to lighter, stronger, and more durable hydraulic cylinders, enhancing the overall performance of skid steer loaders.

Conclusion

The production of hydraulic cylinders for skid steer loaders is a complex and meticulous process that lays the foundation for the machine's performance and reliability. From material selection to final inspection, each step is crucial in ensuring that these components can withstand the demanding conditions of construction and agricultural environments. Understanding the intricacies of hydraulic cylinder manufacturing not only highlights the engineering prowess involved but also underscores the importance of quality and innovation in ensuring operational success in the field. As the industry continues to evolve, manufacturers must remain committed to improving their processes and technologies to meet the ever-growing demands of their customers.

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025