វិច្ឆិកា . 16, 2024 07:06 Back to list

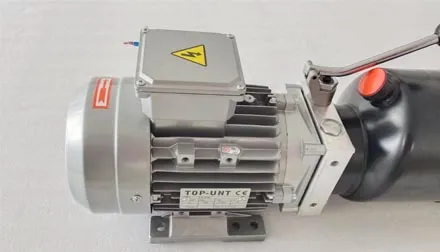

rebuilding a hydraulic cylinder companies

Rebuilding Hydraulic Cylinder Companies Ensuring Efficiency and Longevity

Hydraulic cylinders play a crucial role in various industries, providing the necessary force for machinery to operate effectively. However, like any mechanical component, hydraulic cylinders can wear down over time due to continuous use, leading to reduced efficiency and potential failures. This is where rebuilding hydraulic cylinder companies come into play, offering essential services to restore these vital components to their original functionality.

Understanding Hydraulic Cylinder Rebuilding

Rebuilding a hydraulic cylinder involves a thorough inspection and refurbishment process, which typically includes disassembling the cylinder, replacing worn or damaged parts, and reassembling it to meet the manufacturer's specifications. The goal is to extend the lifespan of the cylinder while maintaining optimal performance. This process not only saves costs compared to purchasing new cylinders but also promotes sustainability by reducing waste.

The Importance of Rebuilding Hydraulic Cylinders

As industries strive to increase efficiency and minimize downtime, the demand for reliable hydraulic systems remains high. Rebuilding hydraulic cylinders can significantly impact operations by

1. Cost-effectiveness Buying new hydraulic cylinders can be a hefty investment, especially for companies that rely on multiple machines. Rebuilding can often save up to 50% of the cost of a new cylinder, making it a financially prudent choice.

2. Environmental Responsibility Rebuilding promotes a more sustainable approach by reducing the need for new materials and minimizing waste. Companies that focus on rebuilding hydraulic cylinders contribute to a circular economy by reusing existing components.

3. Customization and Upgrades Many rebuilding companies offer the option to upgrade components during the rebuilding process, allowing businesses to enhance the performance of their hydraulic systems. This could include installing more durable seals, improved surface finishes, or even modifications to increase the pressure capacity.

rebuilding a hydraulic cylinder companies

4. Minimized Downtime Quick turnaround times in the rebuilding process can minimize the downtime of machinery. Many companies specialize in rapid service, ensuring that hydraulic cylinders are rebuilt and delivered back to the client efficiently.

Choosing the Right Rebuilding Company

When selecting a hydraulic cylinder rebuilding company, several factors should be considered to ensure quality and reliability

1. Experience and Expertise Look for companies with a proven track record in hydraulic cylinder rebuilding. Experienced technicians can identify issues accurately and recommend the best solutions.

2. Quality Standards A reputable rebuilding company should adhere to industry standards and regulations. Inquire about their quality assurance processes to ensure that all rebuilt cylinders meet or exceed OEM specifications.

3. Range of Services Some companies may offer additional services such as cylinder testing, certification, and even on-site support. Having a comprehensive service provider can enhance convenience and reliability.

4. Customer Support Strong customer service is important. A company that values its customers will provide regular updates during the rebuilding process and be available to address any concerns promptly.

Conclusion

Rebuilding hydraulic cylinders is an essential service that benefits industries by improving the longevity and efficiency of their hydraulic systems. By selecting the right rebuilding company, businesses can ensure their machinery operates reliably while also making a cost-effective and environmentally friendly choice. As the demand for hydraulic solutions continues to grow, the role of rebuilding hydraulic cylinder companies will remain integral to the success of modern industries. Investing in professional rebuilding services today sets the foundation for a more productive and sustainable future.

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025