ធ្នូ . 12, 2024 23:57 Back to list

Compact Telescopic Hydraulic Cylinder Manufacturer for Efficient Machinery Solutions

Mini Telescopic Hydraulic Cylinder Factory Innovations and Capabilities

In the realm of hydraulic systems, mini telescopic hydraulic cylinders are becoming increasingly vital across various industries, including construction, manufacturing, and automotive. The demand for compact, high-efficiency hydraulic solutions has driven the growth of specialized factories dedicated to the production of these advanced components. This article delves into the intricacies of a mini telescopic hydraulic cylinder factory, exploring its innovations, manufacturing processes, and the benefits it brings to the marketplace.

Understanding Mini Telescopic Hydraulic Cylinders

Mini telescopic hydraulic cylinders are designed to provide high force in a compact space. Their unique design allows for multiple stages of extension, which means that they can extend significantly while occupying minimal storage space. These cylinders are essential in applications where space is limited and precision is paramount, such as in mobile machinery and small construction equipment. The robust construction and advanced engineering of these cylinders ensure reliability, durability, and performance, meeting the needs of various demanding applications.

Innovations in Design and Engineering

At the heart of a mini telescopic hydraulic cylinder factory is a commitment to innovation. Engineers and designers continuously work on improving cylinder performance through advanced materials and cutting-edge manufacturing techniques. For example, the use of high-strength steel and specialized coatings enhances the longevity and wear resistance of the cylinders. In addition, computer-aided design (CAD) software allows for precise modeling and testing of hydraulic systems, leading to more efficient designs that can handle extreme pressures and varying environmental conditions.

Moreover, advancements in sealing technology have significantly improved the performance and lifespan of these hydraulic cylinders. Modern seals reduce leakage and ensure proper functioning, even in harsh industrial environments. The integration of smart technologies, such as sensors for real-time monitoring, further enhances the capabilities of mini telescopic hydraulic cylinders, allowing for predictive maintenance and increased operational efficiency.

Manufacturing Process From Concept to Completion

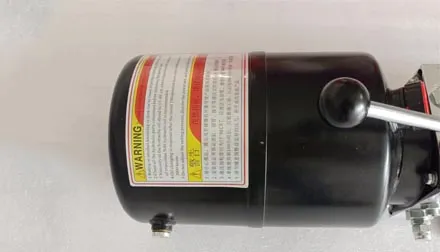

mini telescopic hydraulic cylinder factory

The manufacturing process in a mini telescopic hydraulic cylinder factory typically involves several key stages

1. Material Selection High-quality materials are essential for ensuring durability and performance. Factories often source various steel grades and other components that meet industry standards. 2. Machining Precision machining is critical. CNC (Computer Numerical Control) machines are employed to achieve high tolerances in the cylinder components, including the rods and tubes.

3. Assembly After machining, the components are meticulously assembled. This stage involves the integration of seals, pistons, and hydraulic connections, ensuring that each part functions seamlessly within the system.

4. Testing Rigorous testing protocols are implemented to evaluate the performance of the cylinders. This includes pressure testing, leakage testing, and endurance testing to ensure that they meet or exceed industry standards.

5. Quality Control Quality assurance is paramount in hydraulic component manufacturing. Factories implement stringent quality control measures, examining every detail to ensure reliability before products leave the facility.

Conclusion Meeting Market Demands

The mini telescopic hydraulic cylinder factory serves a crucial role in meeting the growing demands of various industries for reliable, compact hydraulic solutions. With continuous innovation and dedication to quality, these factories not only improve the performance and efficiency of hydraulic systems worldwide but also contribute to the advancement of technology in hydraulic engineering. As industries evolve, the mini telescopic hydraulic cylinder factory stands at the forefront, ready to embrace new challenges and opportunities, ensuring that the future of hydraulic systems is both robust and efficient.

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025