វិច្ឆិកា . 11, 2024 22:39 Back to list

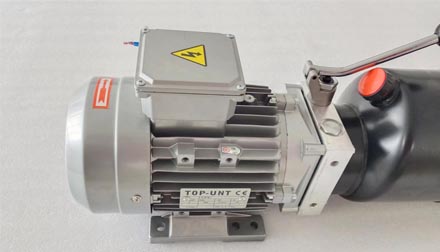

mini hydraulic cylinder factory

The Evolution and Significance of Mini Hydraulic Cylinder Factories

In the world of industrial automation and machinery, mini hydraulic cylinders play a pivotal role. These compact devices are essential in various applications, ranging from automotive and aerospace engineering to construction machinery and agricultural equipment. As industries continue to evolve, the demand for smaller, more efficient hydraulic systems has led to the rise of specialized mini hydraulic cylinder factories.

Understanding Mini Hydraulic Cylinders

Mini hydraulic cylinders are characterized by their compact size, typically designed to generate significant force despite their small footprint. These cylinders operate based on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted undiminished in all directions. This principle allows mini hydraulic cylinders to perform tasks that require heavy lifting, pushing, or manipulating various components.

The applications of mini hydraulic cylinders are vast. They can be found in hydraulic lifts, clamping devices, and even in robotics, where space constraints are a significant concern. Their ability to deliver high force-output in a small casing makes them invaluable in production lines and automated systems.

The Rise of Mini Hydraulic Cylinder Factories

The growing demand for mini hydraulic cylinders has spurred the establishment of dedicated manufacturing facilities. These factories focus specifically on producing high-quality, reliable mini hydraulic cylinders. Factors contributing to this trend include.

1. Increased Automation As industries shift toward automation, the need for precise and efficient hydraulic systems has escalated. Mini hydraulic cylinders provide the perfect solution for compact machinery and robotic systems.

2. Space Constraints In modern industry, space is often at a premium. Mini hydraulic cylinders fit into smaller spaces without sacrificing performance, making them ideal for contemporary machinery.

3. Customization and Specialization Mini hydraulic cylinder factories are increasingly focusing on customizing their products. Different industries require different specifications. Factories are now equipped to design hydraulic solutions tailored to specific applications, enhancing efficiency and effectiveness.

Manufacturing Process

mini hydraulic cylinder factory

The manufacturing of mini hydraulic cylinders involves several critical steps

1. Design and Engineering The process starts with precise designs that incorporate the specific requirements of clients. Advanced CAD software is often used to model the cylinder components accurately.

2. Material Selection High-quality materials, such as alloy steels and high-grade aluminum, are chosen for their strength and durability. The materials must also withstand the high pressures associated with hydraulic systems.

3. Machining Utilizing CNC machines, manufacturers meticulously shape and cut the materials to ensure precision. This step is crucial, as any error can lead to performance issues.

4. Assembly After machining, the components are assembled. This includes fitting seals, rods, and pistons. Quality control is paramount during this phase to ensure that each cylinder meets rigorous standards.

5. Testing Once assembled, each mini hydraulic cylinder undergoes a series of tests, including pressure tests and performance evaluations. This rigorous testing ensures that only reliable products reach the market.

The Future of Mini Hydraulic Cylinder Manufacturing

The future of mini hydraulic cylinder factories looks promising. Technological advancements are constantly improving manufacturing processes, leading to faster production times and better-quality products. The integration of smart technologies, such as IoT (Internet of Things), is gradually being incorporated into hydraulic systems, allowing for real-time monitoring and enhanced operational efficiency.

Moreover, as sustainability becomes a critical focus in industrial production, mini hydraulic cylinder manufacturers are also exploring eco-friendly practices. This includes using recyclable materials and adopting energy-efficient manufacturing processes.

Conclusion

Mini hydraulic cylinder factories represent a dynamic and vital sector of the manufacturing industry. With their ability to produce small yet powerful hydraulic solutions, these factories are at the forefront of meeting the demands of an increasingly automated and efficiency-driven world. As technology advances and industries evolve, the importance of these specialized manufacturers will only continue to grow, solidifying their role in the future of hydraulic engineering.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025