វិច្ឆិកា . 01, 2024 18:26 Back to list

Leading Manufacturer of Double Ended Hydraulic Cylinders for Various Applications

Double-Ended Hydraulic Cylinder Manufacturers An Overview

Double-ended hydraulic cylinders are essential components in various industrial applications, offering efficient operation and high reliability. As the demand for these hydraulic systems continues to grow, manufacturers play a pivotal role in ensuring quality and performance. This article explores the fundamentals of double-ended hydraulic cylinders, their applications, and what to look for in a manufacturer.

A double-ended hydraulic cylinder features a piston that operates from both ends, allowing for bi-directional force and movement. This design provides a significant advantage in applications requiring precise control and balanced force distribution. Common uses include construction machinery, material handling equipment, and machine tool operations. The ability to exert force in both directions makes these cylinders ideal for tasks where space is limited, and efficiency is paramount.

When seeking a manufacturer for double-ended hydraulic cylinders, several factors should be considered. Quality is of utmost importance, as the integrity of the hydraulic system depends on the cylinder's performance. Reputable manufacturers employ stringent quality control measures throughout the production process. They often utilize advanced materials and cutting-edge technology to ensure durability and longevity in their products.

Another critical aspect to evaluate is the manufacturer's experience and expertise in the field. Established manufacturers typically have a wealth of knowledge regarding fluid mechanics, materials science, and hydraulic systems. This expertise allows them to design and build cylinders that meet specific customer requirements while adhering to industry standards.

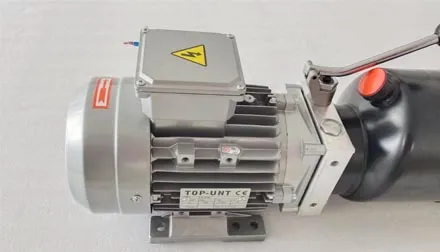

double ended hydraulic cylinder manufacturer

Customization options are also vital. Many industries have unique needs, requiring tailored solutions that standard products may not fulfill. A reliable manufacturer will offer various customization options, including cylinder size, mounting configurations, and material selection, to create a solution that fits seamlessly into the customer's application.

Customer service and support are equally important when choosing a manufacturer. A responsive and knowledgeable support team can assist with technical inquiries, installation guidance, and maintenance advice. Manufacturers that offer comprehensive support and resources can significantly enhance the customer experience and ensure optimal performance of the hydraulic systems.

Lastly, consider the manufacturer's reputation within the industry. Customer testimonials, case studies, and industry certifications can provide valuable insights into the manufacturer’s reliability and competence. Engaging with existing customers can also reveal essential information regarding the manufacturer’s performance and responsiveness.

In summary, selecting a double-ended hydraulic cylinder manufacturer involves careful consideration of quality, experience, customization options, customer support, and reputation. With the right partner, businesses can ensure they receive high-performance hydraulic cylinders that meet their specific needs, ultimately contributing to greater efficiency and productivity in their operations.

-

3x8 Hydraulic Cylinder Product - High Quality OEM Hydraulic Solutions from Trusted Manufacturer

NewsJul.04,2025

-

High-Quality Hydraulic Cylinder of Sanitation Truck Reliable Manufacturers & Factory Price

NewsJul.04,2025

-

Exploring Hydraulic Cylinder Manufacturing for RV Slide-Out Precision, Reliability, Custom Solutions

NewsJun.24,2025

-

Top Hydraulic Downfeed Control Cylinder Companies Reliable Factory-Sourced Hydraulic Downfeed Control Cylinder Supplier

NewsJun.10,2025

-

China County Line Hydraulic Cylinder Supplier - High Quality & Durable County Line Hydraulic Cylinder Factory & Company

NewsJun.10,2025

-

High-Quality China Hydraulic Trailer Jack Cylinder Manufacturer Reliable Hydraulic Trailer Jack Cylinder Factory and Company

NewsJun.10,2025