វិច្ឆិកា . 23, 2024 20:12 Back to list

Tailored All-in-One Hydraulic Cylinder Solutions for Diverse Applications

Custom Self-Contained Hydraulic Cylinders An Overview

Hydraulic systems are integral to various industries, providing efficient force and motion control. Among these systems, the custom self-contained hydraulic cylinder stands out due to its versatility and effectiveness. This article explores the significance, design considerations, advantages, and applications of these cylinders, shedding light on why they are preferred in specific industrial scenarios.

Understanding Self-Contained Hydraulic Cylinders

A self-contained hydraulic cylinder is a compact, integrated unit that combines both hydraulic power and the actuation mechanism in a single assembly. Unlike traditional hydraulic cylinders that require additional components like pumps and reservoirs, self-contained versions house all necessary elements within the cylinder itself. This innovative design streamlines setup and operation, making it an ideal choice for applications that demand space efficiency and simplicity.

Key Design Considerations

When designing a custom self-contained hydraulic cylinder, several factors need to be considered to ensure optimal performance and durability

1. Size and Capacity The dimensions of the cylinder must be tailored to fit the application requirements. This includes determining the stroke length, diameter, and force output based on the tasks it will perform.

2. Material Selection The choice of materials is crucial in maximizing the lifespan and reliability of the cylinder. Common materials include steel, aluminum, and specialized alloys, each offering different strengths and resistance to corrosion and wear.

3. Seal Technology Effective sealing is essential for maintaining pressure and preventing leaks. Custom seals must be chosen based on the operating conditions, including temperature, pressure, and the type of hydraulic fluid used.

4. Operating Environment The intended environment plays a significant role in the design process. Cylinders used in harsh conditions, such as extreme temperatures or exposure to chemicals, may require additional protective coatings or specialized components.

5. Integration with Systems Compatibility with existing machinery and hydraulic systems is another important consideration. Custom solutions often involve collaboration with engineers to develop cylinders that fit seamlessly into the intended application.

Advantages of Custom Self-Contained Hydraulic Cylinders

1. Space Efficiency One of the most significant benefits of self-contained cylinders is their compact design, which reduces the need for external components. This efficiency is particularly valuable in applications where space is at a premium.

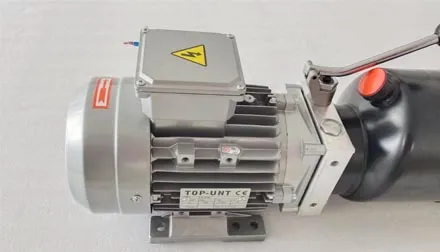

custom self contained hydraulic cylinder

2. Ease of Installation Since these cylinders come as a complete unit, installation is simplified. This reduces downtime during setup and allows for quicker commissioning of machinery.

3. Enhanced Mobility The portability of self-contained units makes them ideal for mobile applications. Whether in construction equipment or manufacturing systems, their lightweight design enhances mobility without sacrificing performance.

4. Reduced Maintenance Custom self-contained hydraulic cylinders are often designed with reliability in mind, resulting in lower maintenance requirements. This can lead to reduced operational costs over time.

5. Custom Solutions The ability to tailor these cylinders to specific application needs means that they can deliver optimal performance in unique scenarios. Customization allows for enhanced functionality, ensuring that the cylinder meets all operational demands.

Applications in Various Industries

Custom self-contained hydraulic cylinders find applications across a multitude of industries, including

- Manufacturing Used in assembly lines, robotic systems, and material handling equipment, these cylinders provide the necessary force for lifting, pushing, or pulling components.

- Construction Hydraulic cylinders are commonly found in construction machinery such as excavators and cranes, where they enable lifting and moving heavy materials.

- Aerospace In aerospace applications, reliability and performance are paramount. Custom hydraulic cylinders are used in landing gear systems, ensuring safety and functionality.

- Automotive The automotive industry utilizes hydraulic cylinders in a variety of ways, from power steering systems to machine tooling.

- Agriculture In agricultural machinery, self-contained hydraulic cylinders support various functions, from steering to lifting loads.

Conclusion

Custom self-contained hydraulic cylinders offer a unique solution to the challenges faced in various industrial applications. Their compact design, ease of installation, and customization options make them a preferred choice for engineers and manufacturers alike. As industries continue to evolve, the demand for efficient, reliable, and high-performance hydraulic solutions will undoubtedly increase, making these innovative cylinders a vital component in the landscape of modern engineering.

-

China Boarding Axle Power Unit Reliable & Custom Solutions

NewsJun.01,2025

-

China Reciprocating Hydraulic Cylinder Manufacturer Durable & Custom Solutions

NewsJun.01,2025

-

Custom-Built 2-Post Lift Power Units High-Performance Hydraulic Systems

NewsJun.01,2025

-

High-Performance Hydraulic Damping Cylinders Manufacturer Superior Power

NewsJun.01,2025

-

Custom Dual Loader Hydraulic Cylinders Manufacturer Durable Solutions

NewsMay.31,2025

-

Custom Ladder Rack Hydraulic Cylinders Heavy-Duty & Tailored Solutions

NewsMay.31,2025