Қаз . 03, 2024 21:11 Back to list

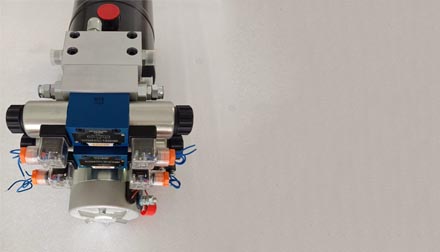

industrial hydraulic cylinder product

Understanding Industrial Hydraulic Cylinders A Key Component in Machinery

Hydraulic cylinders play a crucial role in various industrial applications, providing the necessary force and motion for equipment and machinery. As a key component in hydraulic systems, industrial hydraulic cylinders are designed to convert hydraulic energy into mechanical energy, allowing for the controlled movement of loads. This article delves into the functions, types, and applications of industrial hydraulic cylinders, highlighting their significance in modern engineering.

What is an Industrial Hydraulic Cylinder?

At its core, an industrial hydraulic cylinder consists of a cylindrical tube, a piston, and a rod. When hydraulic fluid is pumped into the cylinder, it creates pressure that forces the piston to move. This movement translates into linear motion, which can be harnessed to perform a multitude of tasks, from lifting heavy loads and pushing machinery to implementing precise movements in manufacturing processes.

Types of Hydraulic Cylinders

There are several types of hydraulic cylinders used across different industries, each optimized for specific applications

1. Single-Acting Cylinders These cylinders use hydraulic pressure to move the piston in one direction, while a spring or gravity returns it to its original position. They are commonly used in applications where the load is only lifted in one direction.

2. Double-Acting Cylinders These are more versatile, allowing movement in both directions by using hydraulic pressure on both sides of the piston. They are widely used in heavy machinery and industrial equipment, where more complex movements are required.

3. Telescopic Cylinders Comprising multiple nested cylinders that extend and retract, these cylinders are ideal for applications requiring long strokes with a compact retracted length, such as dump trucks and aerial lifts.

4. Rotary Actuators While not traditional cylinders, these devices utilize hydraulic pressure to produce rotational movement. They are essential in applications that require turning or rotating machinery.

industrial hydraulic cylinder product

Applications of Industrial Hydraulic Cylinders

Hydraulic cylinders are integral to several sectors, including

- Construction From excavators to cranes, hydraulic cylinders help lift and move heavy materials, facilitating construction projects of all sizes.

- Manufacturing In factories, hydraulic cylinders are used in presses, conveyor systems, and robotic arms, enabling precise and efficient production processes.

- Agriculture Hydraulic cylinders are employed in tractors and other agricultural machinery to control implements such as plows and harvesters.

- Automotive In car manufacturing, hydraulic cylinders are utilized in assembly lines and for tasks like lifting vehicles for repairs.

Advantages of Hydraulic Cylinders

The efficiency and power of hydraulic cylinders offer numerous advantages. They can generate significant force within a relatively small space, are relatively easy to control, and can operate at high speeds when necessary. Moreover, hydraulic systems can be easily integrated into existing machinery, making them a flexible solution for enhancing productivity.

In conclusion, industrial hydraulic cylinders are indispensable in modern machinery and equipment, driving efficiency and functionality across various sectors. Understanding their workings and applications not only underscores their importance in industrial settings but also highlights the technological advancements that enable these vital components to perform effectively in the ever-evolving landscape of engineering.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025