1月 . 13, 2025 13:26 Back to list

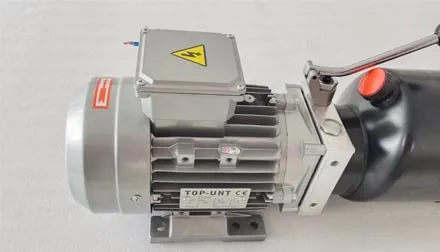

double acting power unit

Hydraulic cylinders are fundamental components in many industrial applications, known for their robustness and ability to handle immense pressure. However, even the highest quality hydraulic cylinders can sometimes face leakage issues, leading to disruptions in operations and potentially costly repairs. Understanding the root causes and solutions for hydraulic cylinder leaks can significantly enhance the reliability and efficiency of machinery.

Oil contamination can exacerbate all these issues. Microscopic particles can enter the system, often from inadequate filtration processes, and lead to accelerated degradation of seals, rods, and barrels. Implementing high-efficiency filtration systems, routinely changing fluids, and monitoring fluid quality can mitigate this risk and enhance the longevity of the entire hydraulic system. When a leak occurs, immediate action is paramount to prevent further damage. Utilizing high-quality repair kits, specifically designed for hydraulic cylinders, ensures that replacements match the original specifications. Additionally, consulting with experts who have deep expertise in hydraulic systems is crucial. Professionals can provide comprehensive diagnostics, ensuring that all potential issues are identified and rectified efficiently. Trustworthiness in the hydraulic industry comes from transparency and reliability. Manufacturers should provide detailed information about cylinder performance, expected wear and tear rates, and maintenance guidelines. Offering training programs for maintenance teams can also empower on-the-ground staff with the knowledge needed to address common issues promptly, reducing downtime and extending the operational life of hydraulic systems. Investing in high-quality hydraulic cylinders and components is a wise choice for any operation. Ensuring proper maintenance, timely replacement of worn parts, and expert consultation can mitigate risks associated with leaks. Through these measures, operations can maintain the effectiveness and reliability of their hydraulic systems, ultimately enhancing productivity and minimizing costs.

Oil contamination can exacerbate all these issues. Microscopic particles can enter the system, often from inadequate filtration processes, and lead to accelerated degradation of seals, rods, and barrels. Implementing high-efficiency filtration systems, routinely changing fluids, and monitoring fluid quality can mitigate this risk and enhance the longevity of the entire hydraulic system. When a leak occurs, immediate action is paramount to prevent further damage. Utilizing high-quality repair kits, specifically designed for hydraulic cylinders, ensures that replacements match the original specifications. Additionally, consulting with experts who have deep expertise in hydraulic systems is crucial. Professionals can provide comprehensive diagnostics, ensuring that all potential issues are identified and rectified efficiently. Trustworthiness in the hydraulic industry comes from transparency and reliability. Manufacturers should provide detailed information about cylinder performance, expected wear and tear rates, and maintenance guidelines. Offering training programs for maintenance teams can also empower on-the-ground staff with the knowledge needed to address common issues promptly, reducing downtime and extending the operational life of hydraulic systems. Investing in high-quality hydraulic cylinders and components is a wise choice for any operation. Ensuring proper maintenance, timely replacement of worn parts, and expert consultation can mitigate risks associated with leaks. Through these measures, operations can maintain the effectiveness and reliability of their hydraulic systems, ultimately enhancing productivity and minimizing costs.

Next:

Latest news

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025