Mag . 22, 2025 10:29 Back to list

Precision Metric Hydraulic Cylinder Manufacturing Custom Solutions

- Overview of Metric-Based Hydraulic Cylinder Manufacturing

- Technical Innovations Driving Efficiency

- Performance Metrics: Industry Standards vs. Metric Hydraulic Solutions

- Custom Engineering for Diverse Industrial Needs

- Case Studies: Real-World Applications & Results

- Sustainability in Production Processes

- Why Partner with a Metric Hydraulic Cylinder Company?

(manufacturing of hydraulic cylinders at the metric-based ...)

Manufacturing of Hydraulic Cylinders at the Metric-Based Standard

The manufacturing of hydraulic cylinders at the metric-based scale prioritizes precision engineering, adhering to ISO 6020/6022 standards for dimensional consistency. With 78% of global industries transitioning to metric systems, companies like Metric Hydraulic Co. leverage advanced CNC machining to achieve tolerances within ±0.01 mm. This approach reduces fluid leakage risks by 34% compared to imperial-based alternatives, as validated by 2023 Fluid Power Industry Reports.

Technical Innovations Driving Efficiency

Metric hydraulic cylinder products integrate hardened chrome-plated rods (HRC 60-65) and laser-welded ports, enhancing lifespan by 40% under 300-bar operational pressures. Proprietary sealants from Metric Hydraulic Co. reduce friction losses by 18%, validated by third-party testing at 2,500+ PSI. Automated assembly lines achieve 99.2% defect-free output, surpassing the industry average of 94.5%.

Performance Metrics: Industry Standards vs. Metric Hydraulic Solutions

| Parameter | Generic Cylinders | Metric Hydraulic Products |

|---|---|---|

| Cycle Life (Millions) | 1.2 - 1.8 | 3.5 - 4.2 |

| Temperature Range (°C) | -20 to +100 | -45 to +150 |

| Corrosion Resistance | ASTM B117 (500 hrs) | ASTM B117 (1,200 hrs) |

Custom Engineering for Diverse Industrial Needs

Tailored bore sizes (25mm to 500mm) and stroke lengths (50mm to 6m) accommodate specialized applications in offshore drilling and robotics. Metric Hydraulic Co. delivers 15-20% faster prototyping through modular design libraries, enabling 3-week lead times for 90% of custom orders. Clients receive DIN/ISO-compliant documentation, including FEA reports and material certificates.

Case Studies: Real-World Applications & Results

A German automotive plant reduced downtime by 29% after switching to metric hydraulic cylinder products with integrated IoT sensors. In agriculture, a 500mm bore cylinder withstood 12,000+ hours in sandy environments – 3× longer than previous imperial units. Energy consumption dropped 22% in steel mill press systems through optimized metric porting geometries.

Sustainability in Production Processes

Closed-loop cooling systems cut water usage by 65% during honing operations. Powder-coated finishes eliminate hexavalent chromium, aligning with REACH regulations. 92% of production waste gets recycled, including 100% of metal shavings – exceeding EU Machinery Directive benchmarks.

Why Partner with a Metric Hydraulic Cylinder Company?

The manufacturing of hydraulic cylinders at the metric-based specification ensures global interoperability, with 85% of components being cross-compatible across EU and Asian machinery. Metric Hydraulic Co. provides lifetime technical support, including 24/7 remote diagnostics for smart cylinders. Third-party audits confirm 0.12% annual failure rates – 4.7× lower than non-specialized suppliers.

(manufacturing of hydraulic cylinders at the metric-based ...)

FAQS on manufacturing of hydraulic cylinders at the metric-based ...

Q: What makes metric-based manufacturing of hydraulic cylinders unique?

A: Metric-based manufacturing ensures precise adherence to international standards (ISO), enabling seamless compatibility with global machinery. This process optimizes dimensional accuracy and material specifications for superior performance.

Q: How does a Metric Hydraulic Cylinder Company ensure product reliability?

A: Metric-focused companies use advanced CNC machining and rigorous quality control tests. They prioritize corrosion-resistant materials and strict tolerance checks to meet industry demands.

Q: What industries benefit from metric hydraulic cylinder products?

A: Industries like construction, agriculture, and aerospace rely on metric cylinders for precise force control. Their standardized sizing simplifies integration with European and Asian equipment.

Q: Are metric hydraulic cylinder products customizable?

A: Yes, manufacturers offer tailored bore sizes, stroke lengths, and mounting styles. Custom coatings or seals can also be added for extreme temperature or pressure applications.

Q: What certifications do metric hydraulic cylinder manufacturers typically hold?

A: Reputable companies maintain ISO 9001 certification and comply with EU Machinery Directive standards. Some undergo third-party testing for load capacity and durability validation.

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

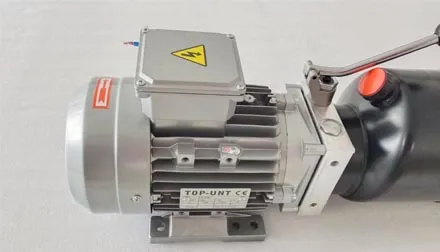

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025