Nov . 16, 2024 04:08 Back to list

car lift hydraulic cylinder factories

The Role of Hydraulic Cylinders in Car Lifts

In the world of automotive repair and maintenance, efficiency and safety are of utmost importance. One crucial component that ensures these factors is the hydraulic cylinder, particularly in the context of car lifts. Hydraulic cylinders are mechanical devices that convert hydraulic energy into linear motion, making them essential in various applications, including automotive lifting systems. In this article, we will explore the significance of hydraulic cylinders in car lifts, the factories that manufacture these devices, and the innovations that continue to shape the industry.

Understanding Hydraulic Cylinders

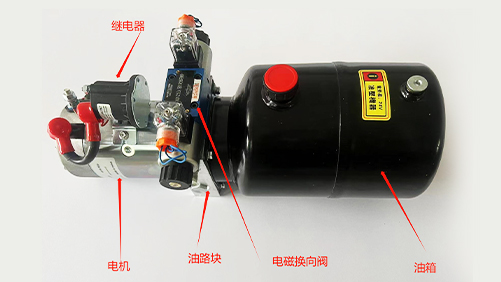

Hydraulic cylinders operate based on Pascal's principle, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. This principle allows hydraulic cylinders to lift substantial weights with relatively little effort, making them ideal for car lifts. They consist of a cylinder barrel, piston, and rod, working in synergy to provide powerful lifting capabilities despite the compact size of the device.

These cylinders can handle hundreds, if not thousands, of pounds, providing the necessary strength to lift vehicles safely off the ground. Car lifts utilize hydraulic cylinders for various purposes, including tire changes, brake repairs, and undercarriage inspections. The reliability and effectiveness of hydraulic systems make them a staple in automotive service centers, enhancing productivity and ensuring that tasks are completed safely.

Car Lift Hydraulic Cylinder Factories

The manufacturing of hydraulic cylinders involves several specialized factories that focus on producing high-quality and durable components

. These factories employ advanced techniques, such as precision machining and quality control processes, to ensure that every cylinder meets rigorous safety and performance standards.Many of these factories incorporate automation and robotics into the manufacturing process, allowing for greater consistency and lower production costs. Moreover, with the increasing demand for sustainable practices, many manufacturers are also looking into eco-friendly materials and production methods. This trend not only reduces the environmental impact but also appeals to a market increasingly concerned with sustainability.

car lift hydraulic cylinder factories

In addition to standard hydraulic cylinders, some factories are also engaged in the production of custom cylinders tailored to specific needs. This customization is vital as different types of car lifts may require unique specifications based on their design and intended use.

Innovations in Hydraulic Cylinder Technology

The world of hydraulic cylinders isn’t static; it is constantly evolving with technological advancements. Recent innovations include the development of advanced sealing materials that reduce leakage and increase longevity. Manufacturers are also exploring the use of smart technologies, integrating sensors that can provide real-time data on the performance of hydraulic systems. This enables better monitoring and maintenance, ultimately extending the lifecycle of the equipment.

Another significant trend is the integration of lightweight materials into hydraulic cylinder designs. This change not only enhances portability but also improves the overall efficiency of car lifts. Lighter cylinders can reduce energy consumption, which is an economic and ecological advantage for automotive service centers looking to operate more sustainably.

Conclusion

In conclusion, hydraulic cylinders are indispensable components in the realm of car lifts. Their ability to lift heavy loads safely and efficiently has made them a standard in automotive service facilities around the world. The factories that produce these hydraulic cylinders play a crucial role in ensuring that high-quality, reliable products are available to meet the demands of the automotive industry.

As technology continues to advance, we can expect further improvements in hydraulic cylinder design and manufacturing processes. With a focus on sustainability, efficiency, and innovation, the future of hydraulic systems in car lifts looks promising, ensuring that they will continue to play a critical role in automotive repair and maintenance for years to come.

-

China Boarding Axle Power Unit Reliable & Custom Solutions

NewsJun.01,2025

-

China Reciprocating Hydraulic Cylinder Manufacturer Durable & Custom Solutions

NewsJun.01,2025

-

Custom-Built 2-Post Lift Power Units High-Performance Hydraulic Systems

NewsJun.01,2025

-

High-Performance Hydraulic Damping Cylinders Manufacturer Superior Power

NewsJun.01,2025

-

Custom Dual Loader Hydraulic Cylinders Manufacturer Durable Solutions

NewsMay.31,2025

-

Custom Ladder Rack Hydraulic Cylinders Heavy-Duty & Tailored Solutions

NewsMay.31,2025