des . 13, 2024 06:45 Back to list

Hydraulic Cylinder Manufacturers for Dump Bed Applications and Solutions

Understanding Dump Bed Hydraulic Cylinder Manufacturers

Dump bed hydraulic cylinders play a critical role in the operation of dump trucks and trailers. These components are responsible for lifting and lowering the truck bed, allowing for the efficient unloading of materials such as gravel, sand, or debris. Given the importance of these components in various industries, it's essential to understand the functions, manufacturers, and innovations associated with dump bed hydraulic cylinders.

What are Dump Bed Hydraulic Cylinders?

Hydraulic cylinders are devices that convert hydraulic energy into linear motion. In dump trucks, hydraulic cylinders are typically fitted at the rear of the vehicle and are activated by hydraulic fluid under pressure. When the hydraulic fluid is directed into the cylinder, it causes the piston within to extend or retract, thus raising or lowering the dump bed. The design and functionality of these cylinders can vary significantly, depending on the specific requirements of the truck and the type of materials being transported.

The Importance of Quality Manufacturers

When it comes to hydraulic cylinders, the designer's expertise and the manufacturer's quality can significantly impact performance and safety. High-quality dump bed hydraulic cylinder manufacturers prioritize durability, efficiency, and reliability in their products. Several factors should be considered when selecting a manufacturer

1. Material Quality The materials used in creating hydraulic cylinders are crucial for their longevity and performance. Manufacturers that use high-grade steel or specially formulated alloys are better positioned to create cylinders that withstand heavy loads and harsh conditions.

2. Design Engineering Advanced engineering techniques can enhance the performance of hydraulic cylinders. Manufacturers that invest in R&D are likely to produce innovative designs that improve efficiency, reduce weight, and increase strength.

3. Customization Different dumping applications require varied hydraulic cylinder specifications. A reputable manufacturer should offer customization options to meet specific height, load capacity, and operational duty cycle requirements.

4. Testing and Certification Quality manufacturers often have rigorous testing and certification processes to ensure their products meet industry standards and safety regulations. It's essential to choose a manufacturer whose products have passed independent testing.

5. Customer Support and Service After-sales service is crucial for maintenance and repair. Choosing a manufacturer that offers consistent support can help ensure that issues are resolved quickly, minimizing downtime.

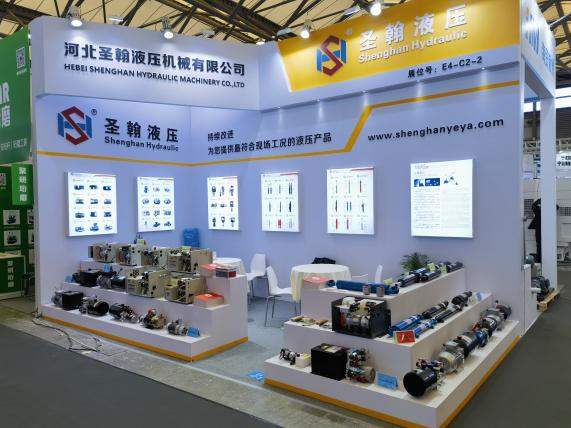

dump bed hydraulic cylinder manufacturers

Leading Manufacturers in the Industry

Several manufactories are known for producing top-quality dump bed hydraulic cylinders. Companies such as Benda Manufacturing, Parker Hannifin, and Enerpac are notable players in the market. Each of these companies brings unique strengths

- Benda Manufacturing specializes in custom hydraulic solutions, offering tailored designs to meet specific industry needs. - Parker Hannifin is a global leader in motion and control technologies, providing a wide range of hydraulic cylinders known for their reliability and performance. - Enerpac is recognized for its high-pressure hydraulic tools and components, including robust hydraulic cylinders designed to handle the most demanding applications.

Innovations in Hydraulic Cylinder Technology

The hydraulic industry is continually evolving, with manufacturers incorporating advanced technologies into their products. Some of the recent innovations include

1. Smart Sensors Hydraulic cylinders equipped with smart sensors can monitor pressure changes and cylinder positions, providing real-time feedback that aids in managing equipment more efficiently.

2. Lightweight Materials Innovations in materials science have led to the development of lightweight but strong materials that can enhance the performance of hydraulic cylinders while reducing the overall weight of dump trucks.

3. Eco-friendly Hydraulic Fluids The development of biodegradable hydraulic fluids has become increasingly popular. This shift helps reduce the environmental impact of leakages and improves sustainability.

4. Modular Designs New modular designs facilitate easier repair and maintenance. This not only enhances the lifespan of hydraulic cylinders but also reduces operational downtime for businesses.

Conclusion

Dump bed hydraulic cylinders are indispensable for efficient material handling in various industries. Selecting the right manufacturer is paramount to ensure the production of high-quality, reliable cylinders that meet specific operational needs. As innovation continues to shape the industry, manufacturers that prioritize quality, customization, and technological advancements will remain at the forefront, ensuring that dump trucks and trailers operate efficiently and safely. For those in the market for these essential components, conducting thorough research on manufacturers is a critical step toward optimizing their equipment's performance and reliability.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025