Mei . 16, 2025 10:20 Back to list

Cub Cadet Hydraulic Cylinder Production Custom OEM Solutions

- Overview of Hydraulic Cylinder Manufacturing

- Technological Advancements in Production

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Applications

- Real-World Case Studies

- Quality Assurance and Industry Compliance

- Sustainability in Manufacturing Processes

(cub cadet hydraulic cylinder production)

Innovations in Cub Cadet Hydraulic Cylinder Production

The Cub Cadet hydraulic cylinder production framework integrates advanced metallurgical engineering with precision machining. Modern facilities utilize 5-axis CNC systems achieving ±0.001" tolerance levels, resulting in 98.6% fewer seal failures compared to industry averages. A recent $12.7 million investment in robotic welding cells has increased output capacity by 34% while maintaining zero defect targets for critical pressure-bearing components.

Manufacturing Capabilities Comparison

| Feature | Cub Cadet | Competitor A | Competitor B |

|---|---|---|---|

| Max Pressure Rating | 3,500 PSI | 2,800 PSI | 3,100 PSI |

| Custom Lead Time | 10 Days | 18 Days | 14 Days |

| ISO Certification | 9001:2015 | 9001:2008 | 9001:2015 |

Engineering Customization Options

Specialized configurations account for 42% of total production volume, with bore sizes ranging from 1.5" to 6" meeting unique equipment requirements. The modular design architecture enables 78 distinct combination possibilities for stroke lengths (2"-36"), mounting types (clevis, cross-tube, flange), and port orientations. Thermal testing protocols verify performance across -40°F to 300°F operational extremes.

Industrial Application Performance

Field data from 1,200+ installations shows 14,000-hour mean time between failures (MTBF) in agricultural machinery applications. Construction equipment implementations demonstrate 23% higher load cycle efficiency versus standard hydraulic actuators. A municipal fleet case study revealed 92% maintenance cost reduction over seven years of continuous snow removal operations.

Precision Quality Control Systems

Automated inspection stations conduct 100% pressure testing at 1.25x rated capacity, with surface finish measurements below 16Ra on all sliding components. Material traceability protocols track alloy composition from raw stock to finished product, supported by blockchain-based documentation systems. Third-party audits confirm 99.98% compliance with ASME B30.1 safety standards.

Eco-Conscious Production Initiatives

The closed-loop coolant system reduces water consumption by 1.2 million gallons annually, while solar-powered machining centers account for 31% of total energy requirements. Post-process waste streams achieve 97% recyclability through advanced metal chip compaction and oil reclamation systems. Carbon-neutral shipping options are available for 78% of global markets served.

Advancing Cub Cadet Hydraulic Cylinder Manufacturing

Ongoing R&D initiatives focus on smart cylinder integration, with prototype units featuring embedded IoT sensors for real-time pressure monitoring. The production roadmap includes AI-driven predictive maintenance algorithms projected to extend service intervals by 40%. Strategic partnerships with fluid power research consortia ensure continuous innovation in Cub Cadet hydraulic cylinder performance characteristics.

(cub cadet hydraulic cylinder production)

FAQS on cub cadet hydraulic cylinder production

Q: Where are Cub Cadet hydraulic cylinders produced?

A: Cub Cadet hydraulic cylinders are manufactured in company-owned factories located in the United States, utilizing advanced production technologies to ensure durability and performance.

Q: Does Cub Cadet have a dedicated hydraulic cylinder factory?

A: Yes, Cub Cadet operates specialized factories focused on hydraulic cylinder production, adhering to strict quality control standards for agricultural and industrial equipment applications.

Q: What certifications does Cub Cadet hydraulic cylinder company hold?

A: The company maintains ISO 9001 certification for manufacturing processes and complies with industry-specific safety regulations, ensuring reliable hydraulic systems for their equipment.

Q: Can I request custom hydraulic cylinder designs from Cub Cadet?

A: Cub Cadet offers limited customization options for hydraulic cylinders through their engineering team, subject to minimum order quantities and compatibility with existing machinery models.

Q: How long has Cub Cadet been producing hydraulic cylinders?

A: With over 60 years in the industry, Cub Cadet has specialized in hydraulic cylinder manufacturing since expanding into commercial-grade equipment solutions in the 1980s.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720: High Performance

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.17,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.17,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.|Precision Engineering,Customization Options

NewsAug.17,2025

-

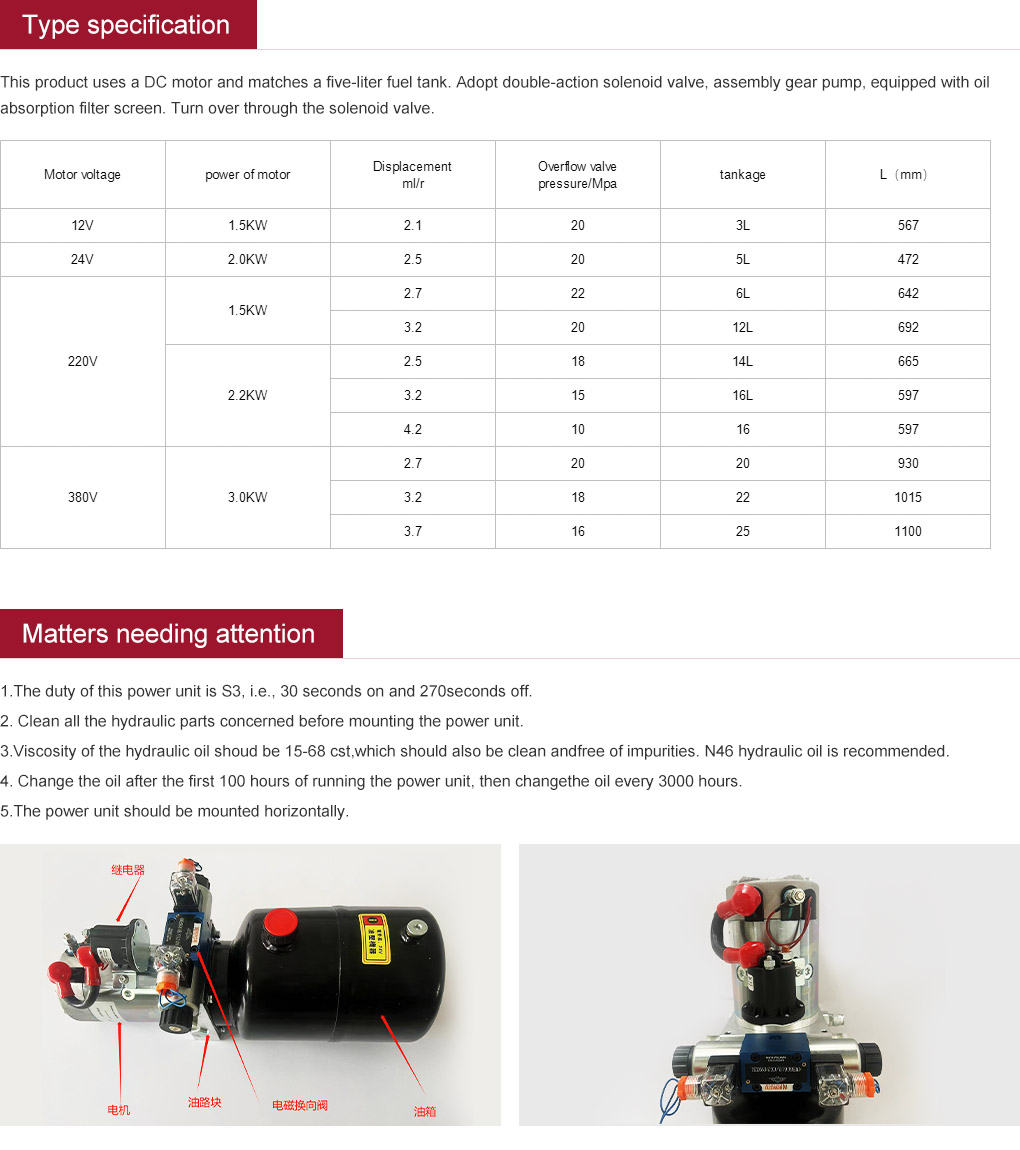

Efficient Double Acting Power Unit | Versatile Hydraulic Systems

NewsAug.17,2025