दिसम्बर . 23, 2024 06:24 Back to list

Effective Methods for Bleeding Hydraulic Cylinders and Ensuring Optimal Performance

Hydraulic Cylinder Bleeding An Essential Process for Optimal Performance

Hydraulic systems are the backbone of many machinery and equipment used across various industries, from manufacturing and construction to automotive and aerospace. A key component of these systems is the hydraulic cylinder, which converts hydraulic energy into mechanical force. However, to ensure that these cylinders function efficiently, a process known as bleeding must be performed. This article explores the importance of hydraulic cylinder bleeding, the methods used to carry it out, and the products and tools available to facilitate this process.

Understanding Hydraulic Cylinder Bleeding

Hydraulic cylinder bleeding refers to the removal of trapped air within a hydraulic system. Air contamination can lead to several issues, severely affecting the performance of hydraulic cylinders. When air enters the hydraulic circuit, it compresses under pressure, leading to a phenomenon known as cavitation. This can result in reduced efficiency, jerky motion, and even damage to the cylinder itself. Therefore, it's critical to bleed hydraulic cylinders regularly to prevent these issues and maintain optimal performance.

Why Bleeding is Necessary

1. Performance Optimization Trapped air can create inconsistent cylinder movement, reducing the efficiency of the entire hydraulic system. By bleeding the system, operators ensure smooth operation and responsiveness.

2. Extending Equipment Life Air within hydraulic systems can lead to excessive wear and tear on components, which can result in premature failure. Regularly bleeding cylinders allows for the proper function and longevity of the equipment.

3. Safety Hydraulic systems often operate under high pressure. Air pockets can lead to unpredictable behavior, which can pose safety risks to operators and nearby personnel. Bleeding the system reduces these risks.

4. Preventing Contamination Air can bring moisture and other contaminants into the hydraulic fluid. Bleeding helps minimize these contaminants, preserving the integrity of the hydraulic fluid and reducing repair costs in the long run.

Methods of Bleeding Hydraulic Cylinders

There are several methods for bleeding hydraulic cylinders, each depending on the design of the system and the preferences of the operator. Some of these methods include

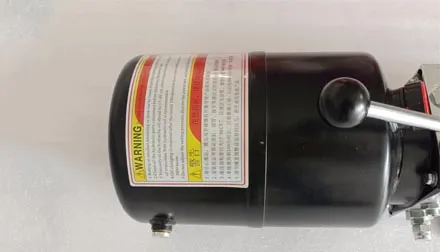

hydraulic cylinder bleeding products

1. Manual Bleeding This straightforward approach involves loosening a bleed valve on the cylinder while the hydraulic system is under pressure. The air will escape as the cylinder is actuated, allowing for the removal of trapped air.

2. Automatic Bleeding Systems Some modern hydraulic systems come equipped with automatic bleeding features that continually purge air without manual intervention. These systems use high-tech sensors and automation to ensure optimal performance consistently.

3. Fluid Exchange Method In some cases, an operator may choose to change the hydraulic fluid entirely while simultaneously bleeding the system. This process can help reduce contamination and improve system performance.

Essential Tools and Products for Effective Bleeding

To efficiently bleed hydraulic cylinders, certain tools and products are highly recommended

1. Hydraulic Bleed Kit These kits typically include hoses, fittings, and valves designed specifically for bleeding hydraulic systems. They simplify the process and reduce the chance of air re-entering the system.

2. Pressure Gauge A pressure gauge is helpful for monitoring the system’s pressure during the bleeding process, ensuring that operators can make necessary adjustments.

3. Fluid Filtration Systems Using a filtration system can help clean hydraulic fluid during exchanges or top-offs, minimizing contamination risks.

4. Lubricants and Sealants Properly sealing any bleed valves after use is vital. The right lubricants and sealants can prevent leaks and ensure the longevity of the connections.

5. Instructional Manuals and Guides It’s essential for operators to have access to clear guidelines regarding the bleeding process for their specific equipment. Manufacturers often provide manuals detailing the best practices for their systems.

In conclusion, hydraulic cylinder bleeding is a crucial process that ensures the longevity, efficiency, and safety of hydraulic systems. By understanding the necessity of this procedure and utilizing the appropriate methods and products, users can maintain optimal performance and prevent costly repairs. Regular maintenance, including bleeding hydraulic cylinders, is essential for any organization relying on hydraulic mechanisms to operate effectively.

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025