जनवरी . 17, 2025 04:30 Back to list

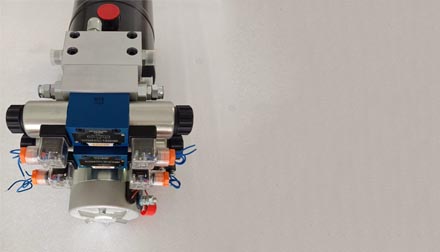

Double acting power units

For industries requiring precision, reliability, and strength, high quality double acting hydraulic press cylinders stand as indispensable components. These cylinders operate with a dual-action mechanism, enabling powerful pushes and pulls within various applications. In sectors such as automotive, aerospace, and manufacturing, where precision and efficiency are critical, opting for a superior hydraulic cylinder can markedly improve operational output and product quality.

The authority of a cylinder's design also lies in safety and compliance. Reputable manufacturers adhere to stringent industry standards and certifications, such as ISO 9001 or ASME regulations, which validate the trustworthiness of their products. This compliance not only assures quality but amplifies the cylinder’s reliability in critical applications where failure is not an option. In terms of user experience, hydraulic cylinders should offer ease of installation and operation. This encompasses clear instruction manuals, available customer support, and comprehensive warranty policies that provide peace of mind to operators and maintenance teams. Additionally, some high quality models feature self-lubricating bearings or environmentally friendly fluid options, which further enhance operational performance and reduce ecological impact. To encapsulate, procuring a high quality double acting hydraulic press cylinder is not merely a purchase but an investment in your production capabilities. Their unmatched strength and reliability streamline processes, boost efficiency, and maintain the highest standards of quality in output. Engaging with trusted suppliers and selecting the right specifications will empower industries to elevate both their manufacturing processes and end products, ensuring competitiveness in today’s fast-evolving market landscape.

The authority of a cylinder's design also lies in safety and compliance. Reputable manufacturers adhere to stringent industry standards and certifications, such as ISO 9001 or ASME regulations, which validate the trustworthiness of their products. This compliance not only assures quality but amplifies the cylinder’s reliability in critical applications where failure is not an option. In terms of user experience, hydraulic cylinders should offer ease of installation and operation. This encompasses clear instruction manuals, available customer support, and comprehensive warranty policies that provide peace of mind to operators and maintenance teams. Additionally, some high quality models feature self-lubricating bearings or environmentally friendly fluid options, which further enhance operational performance and reduce ecological impact. To encapsulate, procuring a high quality double acting hydraulic press cylinder is not merely a purchase but an investment in your production capabilities. Their unmatched strength and reliability streamline processes, boost efficiency, and maintain the highest standards of quality in output. Engaging with trusted suppliers and selecting the right specifications will empower industries to elevate both their manufacturing processes and end products, ensuring competitiveness in today’s fast-evolving market landscape.

Next:

Latest news

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025