दिसम्बर . 29, 2024 20:25 Back to list

heavy duty hydraulic cylinder factories

Understanding Heavy-Duty Hydraulic Cylinder Factories

Heavy-duty hydraulic cylinders are pivotal components in various industrial applications, providing the power and reliability needed to perform demanding tasks. From construction machinery to manufacturing equipment, these cylinders play a vital role in converting hydraulic energy into mechanical force. Consequently, understanding the operations of heavy-duty hydraulic cylinder factories is essential for those involved in industries that rely on these powerful devices.

The Basics of Hydraulic Cylinders

Hydraulic cylinders operate under the principle of Pascal's law, which states that when pressure is applied to a confined fluid, it is transmitted evenly in all directions. In heavy-duty applications, these cylinders are designed to withstand high pressures and deliver significant lifting force. They consist of several key components, including the cylinder barrel, piston, piston rod, and seals, all of which must be manufactured to precise specifications to ensure optimal performance and safety.

The Role of Factories in Manufacturing

Heavy-duty hydraulic cylinder factories play a critical role in producing these complex components. The manufacturing process begins with the selection of high-quality raw materials, such as steel and aluminum alloys, which are chosen for their strength and durability. The factories employ advanced machining techniques, including CNC machining and welding, to create the intricate parts required for each cylinder.

Quality control is paramount in these factories. Due to the high-stakes nature of heavy-duty applications, any failure in a hydraulic cylinder can lead to catastrophic consequences. As such, manufacturers implement stringent quality assurance processes, including rigorous testing of materials and finished products. This ensures that each cylinder meets industry standards and performs reliably under extreme conditions.

Innovation and Technology

As industries evolve, the demand for more efficient and powerful hydraulic systems grows. Heavy-duty hydraulic cylinder factories are at the forefront of this innovation, integrating advanced technologies into their production processes. For instance, computer-aided design (CAD) software allows engineers to create and test cylinder designs virtually before moving to production. This not only speeds up the design process but also minimizes errors and enhances overall efficiency.

heavy duty hydraulic cylinder factories

Moreover, factories are increasingly adopting automation and robotics in their operations. Automated machining centers can produce components with unparalleled precision and consistency, reducing production times and labor costs. Additionally, robotics can assist in assembling hydraulic cylinders, further streamlining the manufacturing process.

Sustainability Practices

With growing awareness of environmental issues, many heavy-duty hydraulic cylinder factories are implementing sustainable practices. This includes waste reduction strategies, such as recycling scrap metal and using eco-friendly lubricants and coolants in the machining process. Furthermore, some manufacturers are investing in energy-efficient machinery to reduce their carbon footprint.

Sustainable practices not only benefit the environment but can also enhance a factory's reputation in the industry. Customers are increasingly looking for partners who prioritize sustainability, and factories that adopt green practices can gain a competitive edge.

Global Market Dynamics

The global market for heavy-duty hydraulic cylinders is influenced by various factors, including economic conditions, infrastructure development, and technological advancements. As economies grow, so does the demand for construction and manufacturing equipment, driving the need for high-quality hydraulic cylinders.

Factories located in regions with strong industrial bases have a significant advantage. For instance, those in North America, Europe, and Asia are well-positioned to cater to the growing demand from various sectors. Moreover, as manufacturers seek to optimize their supply chains, many are exploring partnerships with local suppliers to ensure timely access to materials and components.

Conclusion

Heavy-duty hydraulic cylinder factories are essential to the functioning of numerous industries, providing the tools needed to tackle demanding tasks. Through a combination of advanced manufacturing techniques, rigorous quality control, and a commitment to sustainability, these factories ensure that the hydraulic cylinders meet the ever-evolving needs of the market. As technology continues to advance, the fabrication of hydraulic components will likely become even more efficient, paving the way for innovative solutions that enhance performance and reliability in heavy-duty applications. Understanding the intricacies of these factories not only highlights their importance but also underscores the critical role they play in powering the industrial world.

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

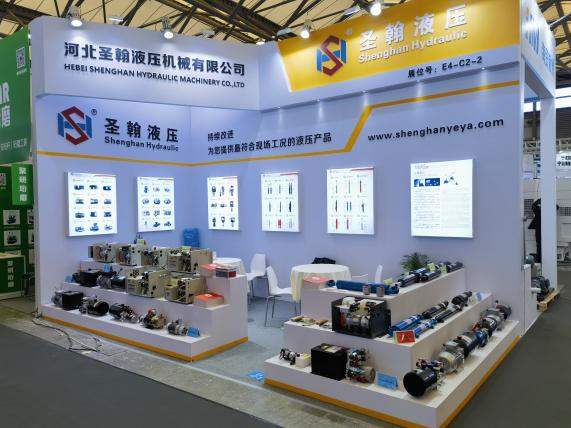

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025