אוק . 07, 2024 03:28 Back to list

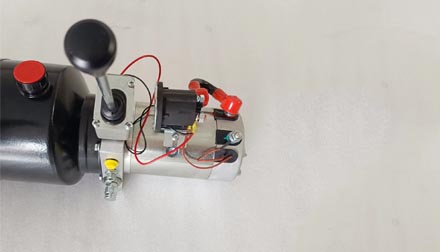

custom hydraulic cylinder pins

The Importance of Custom Hydraulic Cylinder Pins in Modern Machinery

Hydraulic systems play a crucial role in a myriad of industrial applications, from construction machinery to manufacturing equipment. One of the essential components in these hydraulic systems is the hydraulic cylinder, which relies heavily on precisely engineered pins to function effectively. In this article, we will explore the significance of custom hydraulic cylinder pins, their applications, and the benefits of utilizing tailored solutions in hydraulic systems.

Understanding Hydraulic Cylinder Pins

Hydraulic cylinder pins are integral components that connect various parts of the hydraulic system, allowing for smooth movement and the transmission of force. These pins can experience high loads and pressures, which necessitates their design and manufacturing to comply with specific operational requirements. Standard pins can sometimes fall short in terms of performance and compatibility, highlighting the need for custom solutions.

Application of Custom Hydraulic Cylinder Pins

Custom hydraulic cylinder pins can be used across a diverse range of industries. In construction machinery, for example, large excavators and cranes rely on robust hydraulic systems, where custom pins must accommodate particular weight loads while maintaining durability. Similarly, in the aerospace sector, hydraulic systems are critical for aircraft control surfaces, where precision and reliability are paramount. By using custom pins, manufacturers can ensure that the components are tailored to the specific mechanical requirements of the machinery.

Benefits of Customized Solutions

custom hydraulic cylinder pins

1. Precision Engineering Custom hydraulic cylinder pins are designed with precision in mind. This means that they can match the exact specifications required by a particular hydraulic system, reducing the risk of failures related to misalignment or incompatible materials. Precision also enhances the operational efficiency of hydraulic systems, leading to better overall performance.

2. Material Selection When opting for custom solutions, engineers can choose the most suitable materials based on the operating environment. For instance, pins may need to be resistant to corrosion, wear, or extreme temperatures. Customization allows for the selection of high-quality materials that enhance longevity and performance, ensuring that the pins can withstand the rigors of their specific applications.

3. Cost-Effectiveness Although custom parts may involve a higher initial investment compared to off-the-shelf solutions, they tend to be more cost-effective in the long run. Custom pins can reduce maintenance costs and downtime since they are built to last and fit perfectly within their intended systems. This translates into less frequent repairs or replacements and improved machine uptime.

4. Enhanced Performance By using custom hydraulic cylinder pins, machinery can operate at optimal levels. Since these pins are designed to meet precise specifications and performance demands, they contribute to the overall reliability and efficiency of the hydraulic systems. This is particularly vital in industries where precision, reliability, and performance are non-negotiable.

5. Adaptability and Flexibility The needs of industries can evolve over time due to advancements in technology, changes in regulation, or shifts in market demands. Custom hydraulic cylinder pins can be adapted to incorporate upgrades or modifications in hydraulic systems, ensuring that machinery remains relevant and functional as new technologies emerge.

Conclusion

In conclusion, custom hydraulic cylinder pins are indispensable in the world of hydraulic systems. Their ability to cater to specific operational requirements makes them key components in ensuring the reliability, efficiency, and longevity of machinery. As industries continue to adopt advanced technologies and seek higher performance standards, the importance of customized solutions, including hydraulic cylinder pins, will only continue to grow. Investing in custom-engineered components is a proactive approach to enhancing operational effectiveness, proving that quality and precision lead to superior machinery performance.

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025