Dec . 09, 2024 23:10 Back to list

Custom Hydraulic Cylinder for Precise Downfeed Control in Industrial Applications

Custom Hydraulic Downfeed Control Cylinder An Innovation in Precision Engineering

In the world of industrial machinery, precision and reliability are paramount. At the heart of many manufacturing processes lies the effective movement and control of various components, often facilitated by hydraulic systems. Among these systems, one of the notable advancements is the custom hydraulic downfeed control cylinder. This device has transformed how industries approach cutting, drilling, and machining operations by providing enhanced control and efficiency.

Understanding the Hydraulic Downfeed Control Cylinder

A hydraulic downfeed control cylinder is a device that utilizes hydraulic fluid to create controlled downward motion. It is primarily used in applications requiring precise downward pressure, such as in vertical band saws, metal cutting, and other machining tasks. Unlike traditional mechanical systems, hydraulic cylinders offer smooth, adjustable, and controlled motion, significantly improving process accuracy and product quality.

The core function of a hydraulic downfeed control cylinder is to convert hydraulic energy into linear motion. The cylinder comprises a cylinder barrel, piston, and hydraulic fluid, operated under pressure. When hydraulic fluid is pumped into the cylinder, it forces the piston downwards, exerting pressure on the workpiece. This controlled motion allows operators to adjust the feed rate and pressure according to specific material requirements, ensuring optimal cutting performance and minimal waste.

Benefits of Custom Hydraulic Downfeed Control Cylinders

1. Precision Control One of the most significant advantages of a custom hydraulic downfeed control cylinder is the level of precision it offers. Operators can finely tune the downfeed rate to suit the specific characteristics of the material being processed. This capability is critical in industries where tolerances are tight, and quality is non-negotiable.

2. Increased Efficiency Custom hydraulic systems are designed to optimize performance for specific applications. This optimization not only enhances the speed of operations but also reduces downtime and energy consumption. By delivering consistent and reliable performance, these cylinders contribute to a more efficient manufacturing workflow.

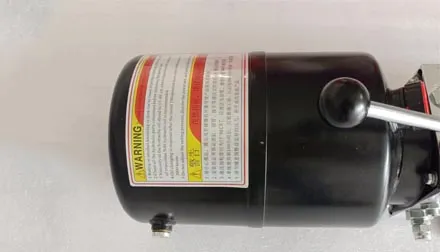

custom hydraulic downfeed control cylinder

3. Durability and Reliability Custom hydraulic downfeed control cylinders are built to withstand the rigors of industrial environments. They are typically constructed from high-quality materials that resist wear, corrosion, and pressure fatigue. This durability ensures a longer lifespan compared to standard systems, providing a better return on investment for manufacturers.

4. Versatility Custom solutions can be designed to meet the unique needs of various applications. Whether for heavy-duty cutting machines or delicate machining processes, hydraulic downfeed cylinders can be tailored in size, pressure ratings, and features, making them suitable for a wide range of industries, from automotive to aerospace.

5. Enhanced Safety Features Modern hydraulic systems often incorporate advanced safety features such as overload protection and integrated sensors. These elements help to prevent accidents and ensure the protection of both the machinery and operators, creating a safer working environment.

Applications Across Industries

The versatility of custom hydraulic downfeed control cylinders opens up a multitude of applications across various industries. In woodworking, these cylinders provide precise control for band saws, allowing for smooth cuts and reducing the risk of material defects. In metalworking, they are essential for ensuring accurate and efficient machining processes, particularly where high pressure and specific feed rates are required.

Moreover, in the automotive industry, where precision is critical, these cylinders are employed in various assembly processes, ensuring that components are assembled with the utmost accuracy. Additionally, they play a crucial role in the aerospace sector, where the demand for precision engineering is at its peak.

Conclusion

The custom hydraulic downfeed control cylinder represents a significant advancement in manufacturing technology. By offering precision control, increased efficiency, durability, and versatility, these cylinders play an essential role in modern industrial processes. As industries continue to evolve and require more sophisticated machinery, the importance of such hydraulic systems cannot be overstated. Investing in custom hydraulic downfeed control cylinders is not merely a choice; it is a strategic decision that enables businesses to enhance productivity, reduce waste, and maintain high-quality standards in their operations. With ongoing advancements in hydraulic technology, the future looks promising for manufacturers looking to leverage the advantages of these innovative systems.

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720: High Performance

NewsAug.18,2025