Nov . 01, 2024 12:49 Back to list

Hydraulic Downfeed Cylinder Manufacturing Processes and Best Practices for High Efficiency

Hydraulic Downfeed Cylinder Factories A Comprehensive Overview

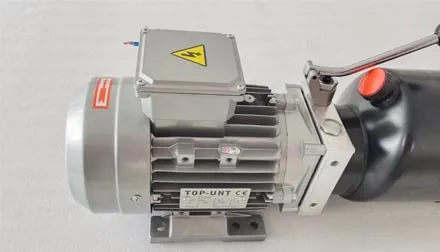

Hydraulic downfeed cylinders are crucial components in various industrial applications, particularly in manufacturing and machining processes. These cylinders are designed to provide stable and controlled downward force, facilitating efficient operations in equipment such as band saws, presses, and other machinery that require precise material handling. Understanding the dynamics of hydraulic downfeed cylinder factories sheds light on their production processes, innovations, and the significance of quality control in delivering reliable products.

At the core of any hydraulic downfeed cylinder factory is an intricate system of manufacturing processes. The production typically begins with the selection of high-quality raw materials, such as steel and aluminum alloys, known for their durability and strength. These materials are then subjected to various engineering processes, including machining and welding, to create the cylinder's components. Precision is paramount, as even the slightest deviation in measurements can lead to inefficiencies or malfunctions during operation.

Once the parts are fabricated, they undergo rigorous assembly procedures. Skilled technicians utilize advanced machinery to ensure that each component fits perfectly, enabling the cylinder to function efficiently under pressure. The assembly line is often designed for flexibility, allowing factories to adapt to different specifications based on customer requirements. This customization capability is a significant advantage, as it enables manufacturers to cater to diverse industries such as construction, automotive, and aerospace.

hydraulic downfeed cylinder factories

Quality control is another critical aspect of hydraulic downfeed cylinder production. Factories implement stringent testing protocols to evaluate the performance and safety of the cylinders before they reach the market. This includes pressure testing, performance testing, and inspections for defects in materials or workmanship. Ensuring that every cylinder meets industry standards is vital for maintaining a factory’s reputation and customer trust.

Innovations in hydraulic technology are also shaping the future of downfeed cylinder production. Many factories are investing in research and development to enhance the efficiency and performance of their products. This includes the integration of smart technology, allowing for real-time monitoring of operational parameters, which can lead to predictive maintenance and reduced downtime.

In conclusion, hydraulic downfeed cylinder factories are at the forefront of industrial manufacturing, providing essential components that support a wide array of applications. Their commitment to quality and innovation ensures that industries can rely on these cylinders for efficient and safe operations. As technology continues to evolve, these factories will likely play a pivotal role in advancing hydraulic systems, contributing to increased productivity and enhanced operational capabilities across various sectors.

-

Exploring Hydraulic Cylinder Manufacturing for RV Slide-Out Precision, Reliability, Custom Solutions

NewsJun.24,2025

-

Top Hydraulic Downfeed Control Cylinder Companies Reliable Factory-Sourced Hydraulic Downfeed Control Cylinder Supplier

NewsJun.10,2025

-

China County Line Hydraulic Cylinder Supplier - High Quality & Durable County Line Hydraulic Cylinder Factory & Company

NewsJun.10,2025

-

High-Quality China Hydraulic Trailer Jack Cylinder Manufacturer Reliable Hydraulic Trailer Jack Cylinder Factory and Company

NewsJun.10,2025

-

Custom China Car Carrier Hydraulic Cylinder Durable & High-Performance

NewsJun.10,2025

-

Northern Tool Hydraulic Power Unit Products High-Efficiency Solutions

NewsJun.10,2025