Ògmh . 16, 2024 14:24 Back to list

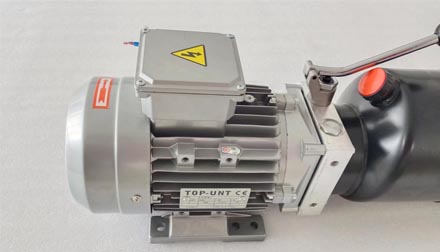

Hydraulic cylinder for Shop Press product.

Exploring the Versatility of Shop Press Hydraulic Cylinders in Manufacturing

In the dynamic landscape of manufacturing, the shop press hydraulic cylinder stands as a testament to engineering innovation and precision. These robust components are integral to a variety of industrial applications, where their ability to exert controlled force in diverse environments is paramount. Let’s delve into the world of shop press hydraulic cylinder products, examining their construction, operation, and the multitude of roles they play in shaping the manufactured goods that support our daily lives.

At the heart of these devices lies the principle of hydraulics, where fluid is used to transmit power. A shop press hydraulic cylinder typically consists of a sturdy cylinder body, a reciprocating plunger or rod, and seals to prevent leakage. When hydraulic fluid is introduced under pressure, it acts on the plunger, which then extends from the cylinder, converting the fluid energy into linear force. This mechanism allows for tremendous force to be generated with minimal space and complexity.

The design and construction of these cylinders prioritize strength and durability. They are often made from high-grade steel or aluminum, materials chosen for their ability to withstand substantial pressures without deformation. The internal surfaces are finely honed to reduce friction and extend seal life, ensuring smooth operation even under heavy loads. Additionally, many shop press hydraulic cylinders feature portability and ease of integration into existing systems, making them versatile tools for both stationary and mobile applications.

In action, the versatility of shop press hydraulic cylinders is evident across various sectors. In metalworking, they might be found in pressing machines, coining operations, or forging presses, where their precise force application can shape metals into intricate forms In metalworking, they might be found in pressing machines, coining operations, or forging presses, where their precise force application can shape metals into intricate forms In metalworking, they might be found in pressing machines, coining operations, or forging presses, where their precise force application can shape metals into intricate forms In metalworking, they might be found in pressing machines, coining operations, or forging presses, where their precise force application can shape metals into intricate forms

In metalworking, they might be found in pressing machines, coining operations, or forging presses, where their precise force application can shape metals into intricate forms In metalworking, they might be found in pressing machines, coining operations, or forging presses, where their precise force application can shape metals into intricate forms shop press hydraulic cylinder product. Automotive manufacturing relies on them for everything from stamping car body panels to driving mechanical presses that cut and form metal parts. In the aerospace industry, these cylinders are instrumental in quality control tests, applying consistent force to ensure the integrity of aircraft components.

Beyond the realm of heavy industry, shop press hydraulic cylinders also find utility in less conventional settings. In agriculture, they can be part of machinery used to process crops or move heavy bales of hay. Civil engineering projects use them in equipment for driving piles or operating clamshell diggers. Even in the world of arts and crafts, miniature versions of these cylinders can be found in homemade metalworking shops or in DIY projects requiring controlled force application.

The adaptability of shop press hydraulic cylinders is further enhanced by the availability of custom designs tailored to specific needs. Whether it's a unique size requirement, a specific force output, or compatibility with certain types of fluids, manufacturers can often accommodate such specifications, expanding the range of possible applications for these devices.

In conclusion, the shop press hydraulic cylinder product embodies a confluence of engineering prowess and adaptability. Its fundamental role in exerting controlled force across industries is a testament to its importance in modern manufacturing. As technology advances, we can expect these cylinders to become even more efficient and ubiquitous, continuing to drive progress in the production of goods that shape our world.

shop press hydraulic cylinder product. Automotive manufacturing relies on them for everything from stamping car body panels to driving mechanical presses that cut and form metal parts. In the aerospace industry, these cylinders are instrumental in quality control tests, applying consistent force to ensure the integrity of aircraft components.

Beyond the realm of heavy industry, shop press hydraulic cylinders also find utility in less conventional settings. In agriculture, they can be part of machinery used to process crops or move heavy bales of hay. Civil engineering projects use them in equipment for driving piles or operating clamshell diggers. Even in the world of arts and crafts, miniature versions of these cylinders can be found in homemade metalworking shops or in DIY projects requiring controlled force application.

The adaptability of shop press hydraulic cylinders is further enhanced by the availability of custom designs tailored to specific needs. Whether it's a unique size requirement, a specific force output, or compatibility with certain types of fluids, manufacturers can often accommodate such specifications, expanding the range of possible applications for these devices.

In conclusion, the shop press hydraulic cylinder product embodies a confluence of engineering prowess and adaptability. Its fundamental role in exerting controlled force across industries is a testament to its importance in modern manufacturing. As technology advances, we can expect these cylinders to become even more efficient and ubiquitous, continuing to drive progress in the production of goods that shape our world.

In metalworking, they might be found in pressing machines, coining operations, or forging presses, where their precise force application can shape metals into intricate forms In metalworking, they might be found in pressing machines, coining operations, or forging presses, where their precise force application can shape metals into intricate forms

In metalworking, they might be found in pressing machines, coining operations, or forging presses, where their precise force application can shape metals into intricate forms In metalworking, they might be found in pressing machines, coining operations, or forging presses, where their precise force application can shape metals into intricate forms shop press hydraulic cylinder product. Automotive manufacturing relies on them for everything from stamping car body panels to driving mechanical presses that cut and form metal parts. In the aerospace industry, these cylinders are instrumental in quality control tests, applying consistent force to ensure the integrity of aircraft components.

Beyond the realm of heavy industry, shop press hydraulic cylinders also find utility in less conventional settings. In agriculture, they can be part of machinery used to process crops or move heavy bales of hay. Civil engineering projects use them in equipment for driving piles or operating clamshell diggers. Even in the world of arts and crafts, miniature versions of these cylinders can be found in homemade metalworking shops or in DIY projects requiring controlled force application.

The adaptability of shop press hydraulic cylinders is further enhanced by the availability of custom designs tailored to specific needs. Whether it's a unique size requirement, a specific force output, or compatibility with certain types of fluids, manufacturers can often accommodate such specifications, expanding the range of possible applications for these devices.

In conclusion, the shop press hydraulic cylinder product embodies a confluence of engineering prowess and adaptability. Its fundamental role in exerting controlled force across industries is a testament to its importance in modern manufacturing. As technology advances, we can expect these cylinders to become even more efficient and ubiquitous, continuing to drive progress in the production of goods that shape our world.

shop press hydraulic cylinder product. Automotive manufacturing relies on them for everything from stamping car body panels to driving mechanical presses that cut and form metal parts. In the aerospace industry, these cylinders are instrumental in quality control tests, applying consistent force to ensure the integrity of aircraft components.

Beyond the realm of heavy industry, shop press hydraulic cylinders also find utility in less conventional settings. In agriculture, they can be part of machinery used to process crops or move heavy bales of hay. Civil engineering projects use them in equipment for driving piles or operating clamshell diggers. Even in the world of arts and crafts, miniature versions of these cylinders can be found in homemade metalworking shops or in DIY projects requiring controlled force application.

The adaptability of shop press hydraulic cylinders is further enhanced by the availability of custom designs tailored to specific needs. Whether it's a unique size requirement, a specific force output, or compatibility with certain types of fluids, manufacturers can often accommodate such specifications, expanding the range of possible applications for these devices.

In conclusion, the shop press hydraulic cylinder product embodies a confluence of engineering prowess and adaptability. Its fundamental role in exerting controlled force across industries is a testament to its importance in modern manufacturing. As technology advances, we can expect these cylinders to become even more efficient and ubiquitous, continuing to drive progress in the production of goods that shape our world. Latest news

-

Exploring Hydraulic Cylinder Manufacturing for RV Slide-Out Precision, Reliability, Custom Solutions

NewsJun.24,2025

-

Top Hydraulic Downfeed Control Cylinder Companies Reliable Factory-Sourced Hydraulic Downfeed Control Cylinder Supplier

NewsJun.10,2025

-

China County Line Hydraulic Cylinder Supplier - High Quality & Durable County Line Hydraulic Cylinder Factory & Company

NewsJun.10,2025

-

High-Quality China Hydraulic Trailer Jack Cylinder Manufacturer Reliable Hydraulic Trailer Jack Cylinder Factory and Company

NewsJun.10,2025

-

Custom China Car Carrier Hydraulic Cylinder Durable & High-Performance

NewsJun.10,2025

-

Northern Tool Hydraulic Power Unit Products High-Efficiency Solutions

NewsJun.10,2025