Gearr . 13, 2025 00:08 Back to list

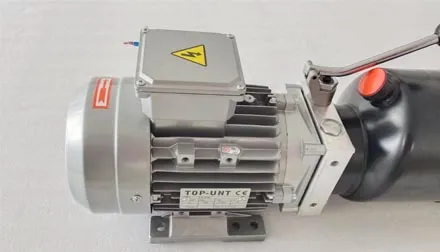

double acting power unit

The realm of underwater hydraulic cylinders is a niche yet pivotal aspect in the broader hydraulic equipment industry, serving crucial roles in oceanographic research, marine construction, and subsea oil extraction. These hydraulic devices, known for their robust performance in extreme conditions, offer engineers and technicians specialized tools to tackle tasks where reliability and precision define success.

Trustworthiness in the performance of these cylinders is non-negotiable, as failure in deep-sea operations can lead to dire consequences. As technology progresses, manufacturers continuously improve the design and materials used to manufacture these cylinders, frequently testing them under simulated conditions that mimic the intense pressures experienced at oceanic depths. This rigorous testing phase aims to iron out any failures, ensuring the product’s performance remains uncompromised under real working conditions. From an authoritative standpoint, manufacturers often collaborate with marine research institutions to innovate and improve the efficacy of underwater hydraulic systems. Several case studies outline successful collaborations wherein new prototypes are field-tested during marine research expeditions, offering invaluable insights that feed back into the design and manufacturing cycles. These collaborative efforts are documented in various research publications, establishing a benchmark in hydraulic cylinder design and development. The expertise required to manufacture and maintain these cylinders extends to a deep familiarity with both mechanical engineering principles and the specific challenges posed by the underwater environment. Technicians trained in aquatic system dynamics are often involved in both the configuration and routine maintenance of these systems, ensuring they are in optimal working condition through regular inspections and servicing. In conclusion, underwater hydraulic cylinders are indispensable tools made to withstand the challenging underwater environment while providing the precision and reliability needed for a variety of applications ranging from marine research and construction to energy extraction. The innovation driving their development is a testimony to the unceasing quest for excellence in hydraulic engineering, ensuring that industries reliant on these devices can operate smoothly, safely, and efficiently. As advancements continue, these hydraulic systems will likely become more sophisticated, setting new standards in underwater operations.

Trustworthiness in the performance of these cylinders is non-negotiable, as failure in deep-sea operations can lead to dire consequences. As technology progresses, manufacturers continuously improve the design and materials used to manufacture these cylinders, frequently testing them under simulated conditions that mimic the intense pressures experienced at oceanic depths. This rigorous testing phase aims to iron out any failures, ensuring the product’s performance remains uncompromised under real working conditions. From an authoritative standpoint, manufacturers often collaborate with marine research institutions to innovate and improve the efficacy of underwater hydraulic systems. Several case studies outline successful collaborations wherein new prototypes are field-tested during marine research expeditions, offering invaluable insights that feed back into the design and manufacturing cycles. These collaborative efforts are documented in various research publications, establishing a benchmark in hydraulic cylinder design and development. The expertise required to manufacture and maintain these cylinders extends to a deep familiarity with both mechanical engineering principles and the specific challenges posed by the underwater environment. Technicians trained in aquatic system dynamics are often involved in both the configuration and routine maintenance of these systems, ensuring they are in optimal working condition through regular inspections and servicing. In conclusion, underwater hydraulic cylinders are indispensable tools made to withstand the challenging underwater environment while providing the precision and reliability needed for a variety of applications ranging from marine research and construction to energy extraction. The innovation driving their development is a testimony to the unceasing quest for excellence in hydraulic engineering, ensuring that industries reliant on these devices can operate smoothly, safely, and efficiently. As advancements continue, these hydraulic systems will likely become more sophisticated, setting new standards in underwater operations.

Latest news

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025