Dec . 12, 2024 13:08 Back to list

making hydraulic cylinder products

The Process of Making Hydraulic Cylinder Products

Hydraulic cylinders are essential components in various industries, including construction, manufacturing, and automotive. They play a crucial role in converting hydraulic energy into mechanical force and are widely used in machinery such as excavators, forklifts, and other heavy equipment. The process of making hydraulic cylinder products involves several key steps, each crucial to ensuring functionality, durability, and efficiency.

Materials Selection

The first step in producing hydraulic cylinders is selecting the right materials. Steel is the most common material used due to its high strength and durability. Depending on the application, manufacturers may choose carbon steel, stainless steel, or alloy steel. Each type of steel has unique properties that cater to different operational environments, such as resistance to corrosion and wear. Additionally, seals and o-rings made from elastomers are carefully selected to ensure they can withstand high pressures and varying temperatures.

Design and Engineering

Once materials are selected, the next phase is design and engineering. Using computer-aided design (CAD) software, engineers create detailed blueprints that outline the dimensions and specifications of the hydraulic cylinder. Key design elements include the cylinder bore, rod diameter, stroke length, and mounting options. The engineers must also consider factors such as load capacity and operating pressure, as these will significantly influence the cylinder’s performance.

Manufacturing Components

The manufacturing process begins with cutting the raw materials to the required dimensions. The cylinder tube is typically produced by using a process such as seamless tube formation or welded assemblies. Precision machining is then utilized to create the inner surface of the cylinder and to manufacture the piston and rod. CNC (Computer Numerical Control) machines are employed for this purpose due to their high precision and efficiency. Machining ensures that the components meet strict tolerances, which is crucial for preventing leaks and ensuring smooth operation.

making hydraulic cylinder products

Surface Treatment

After machining, the components are subjected to surface treatments to enhance their durability and resistance to wear. Common treatments include honing, which smoothens the inner surface, and hard chroming, which provides a protective layer that reduces friction and increases lifespan. The external surface may also be painted or coated to prevent corrosion and improve aesthetics.

Assembly

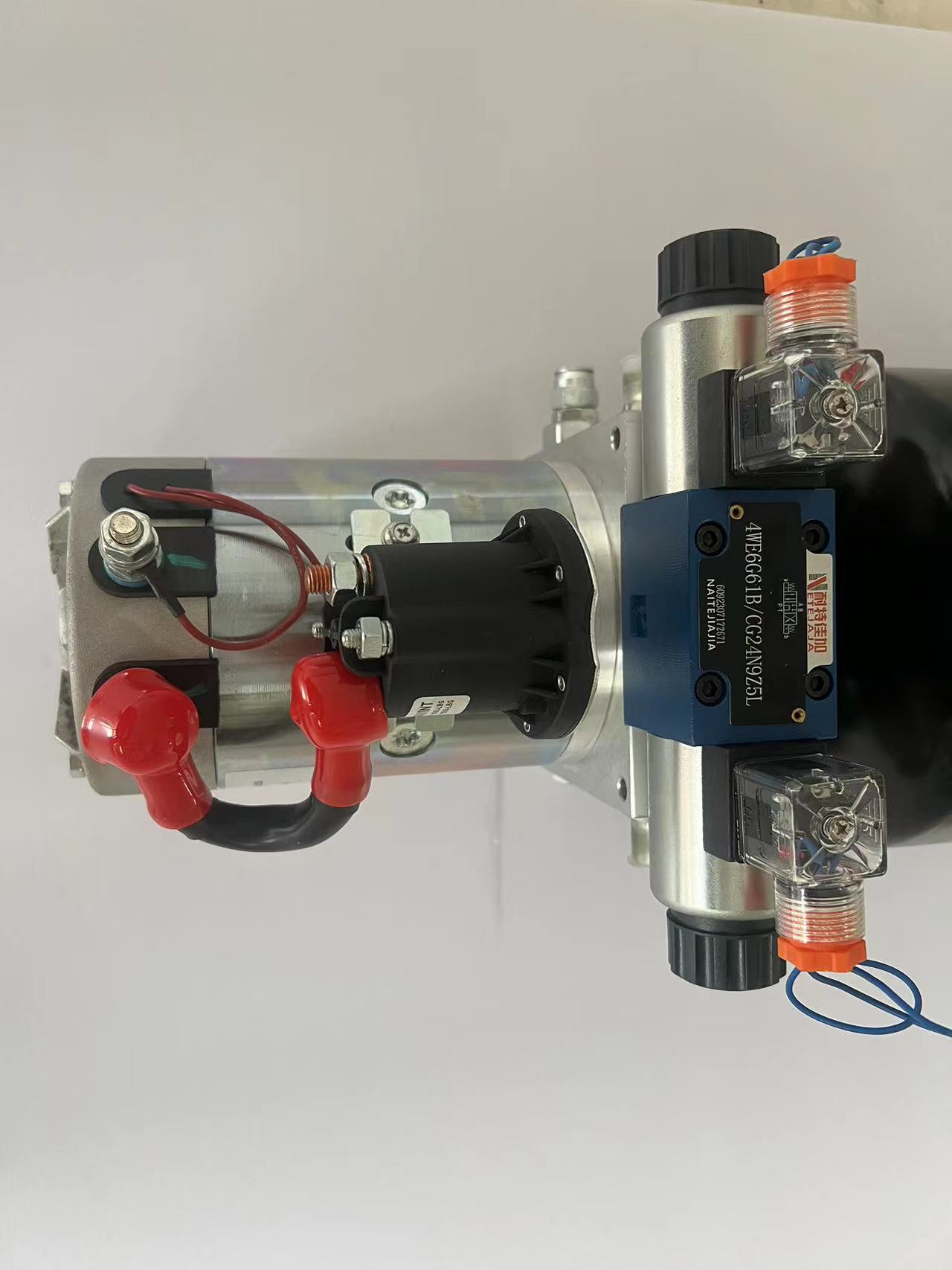

With all components ready, the assembly process begins. Each hydraulic cylinder is constructed by carefully fitting the piston into the cylinder tube, connecting the rod, and sealing it to prevent fluid leakage. It is crucial that all components fit together tightly to maintain the cylinder’s integrity under pressure. Skilled technicians perform this assembly while adhering to strict quality control measures, ensuring that every unit meets the desired standards.

Testing and Quality Control

Quality control is a vital aspect of the hydraulic cylinder manufacturing process. Each completed unit undergoes thorough testing to ensure that it performs to specifications. Hydrostatic tests are commonly conducted to check for leaks and ensure that the cylinder can withstand its rated pressure. Additionally, technicians may perform functional tests to verify the cylinder's operational efficiency.

Conclusion

The making of hydraulic cylinder products is a complex process that requires precision, engineering expertise, and stringent quality control. Each component must be carefully crafted, assembled, and tested to ensure reliability and performance in challenging environments. As industries continue to demand more effective hydraulic solutions, advancements in manufacturing technologies promise to enhance the capabilities and efficiency of hydraulic cylinder products. The future of hydraulic systems looks promising, as innovation fuels the continual enhancement of these vital components.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Hebei Shenghan

NewsAug.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Precision Hydraulic Solutions

NewsAug.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan Hydraulic Machinery Co., Ltd.|Precision Manufacturing&Customization

NewsAug.13,2025

-

Heavy-Duty Snowplow Power Units for Optimal Performance

NewsAug.13,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Engineering&Durable Components

NewsAug.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solutions, Heavy-Duty Lifting

NewsAug.12,2025