Dec . 23, 2024 13:26 Back to list

Exploring High-Performance Displacement Hydraulic Cylinder Solutions for Various Applications

Understanding Displacement Hydraulic Cylinder Products Key Features and Applications

Hydraulic cylinders are essential components in various industrial applications, providing the necessary force and motion for many machines and systems. Among the different types of hydraulic cylinders, displacement hydraulic cylinders stand out due to their design and functionality. This article explores the features, advantages, and applications of displacement hydraulic cylinder products, providing a comprehensive overview for engineers, manufacturers, and end-users in the industry.

What Are Displacement Hydraulic Cylinders?

Displacement hydraulic cylinders are devices that convert hydraulic energy into mechanical energy. They operate based on Pascal’s principle, where an incompressible fluid is used to transmit force. The term displacement refers to the volume of hydraulic fluid that is required to move the cylinder’s piston a certain distance. The relationship between the fluid's pressure and the cylinder's displacement is critical for designing efficient hydraulic systems.

Typically, hydraulic cylinders consist of a cylindrical barrel, a piston, and hydraulic fluid. As fluid is pumped into the cylinder under pressure, it pushes the piston in one direction, creating linear motion. The displacement is determined by the piston area and the stroke length, allowing for a wide range of force outputs.

Key Features of Displacement Hydraulic Cylinders

1. Variable Displacement One of the most significant features of displacement hydraulic cylinders is their ability to provide variable displacement. This means that the volume of hydraulic fluid can be adjusted according to the needs of the application, providing greater flexibility in operation.

2. Compact Design Displacement hydraulic cylinders are often designed to be compact, making them suitable for applications with limited space. Their compactness allows for easy integration into various machines.

3. High Efficiency These cylinders are designed to minimize energy loss during operation. By optimizing the fluid dynamics within the cylinder, they ensure that a larger proportion of the energy input translates into effective mechanical output.

4. Durability and Reliability Constructed from high-quality materials resistant to wear and corrosion, displacement hydraulic cylinders are built to withstand high pressures and harsh operating conditions. This durability ensures long-term performance and reliability.

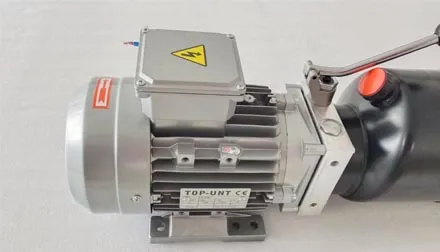

displacement hydraulic cylinder products

5. Ease of Maintenance Many displacement hydraulic cylinders are designed with maintenance in mind. Features such as easy access to key components and the use of self-lubricating materials reduce the overall maintenance burden.

Applications of Displacement Hydraulic Cylinders

The versatility of displacement hydraulic cylinders allows them to be used across a wide range of industries. Some notable applications include

1. Construction Equipment Displacement hydraulic cylinders play a crucial role in heavy machinery such as excavators, bulldozers, and cranes. They provide the necessary force to lift, push, and manipulate heavy materials on construction sites.

2. Manufacturing In manufacturing processes, these cylinders are used in automation systems, assembly lines, and material handling equipment. Their precise control of motion is vital in ensuring efficiency and accuracy in production.

3. Aerospace and Automotive The aerospace and automotive industries utilize displacement hydraulic cylinders for various purposes, from operating landing gear to managing assembly processes in vehicle production.

4. Marine Applications In marine environments, displacement hydraulic cylinders are employed to manage rudders, lifting applications on ships, and other critical functions where reliability and strength are required.

Conclusion

Displacement hydraulic cylinder products are integral to many industries, providing necessary force and movement with precision and efficiency. Their ability to offer variable displacement, durability, and ease of maintenance makes them ideal for rigorous applications across construction, manufacturing, aerospace, and marine sectors. As technology continues to evolve, the development of more advanced displacement hydraulic cylinder designs will undoubtedly further enhance their performance and expand their applications, solidifying their role as indispensable components in modern mechanical systems.

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025