Urr . 14, 2024 17:32 Back to list

Manufacturers of Pneumatic and Hydraulic Cylinders for Industrial Applications

Exploring the World of Pneumatic and Hydraulic Cylinder Factories

In today's industrial landscape, the demand for efficient and reliable machinery is paramount, and at the heart of many automated systems are pneumatic and hydraulic cylinders. These essential components convert energy into mechanical motion, making tasks safer, faster, and more efficient. As industries continue to evolve, the role of factories specializing in the manufacturing of pneumatic and hydraulic cylinders becomes increasingly significant.

Understanding Pneumatic and Hydraulic Cylinders

Before delving into the factories that produce them, it is important to understand the distinctions between pneumatic and hydraulic cylinders. Pneumatic cylinders utilize compressed air to create motion, making them ideal for applications where speed and energy efficiency are critical. They are often used in packaging, assembly lines, and robotic systems.

On the other hand, hydraulic cylinders use pressurized fluid, typically oil, to generate force. This setup allows them to handle heavier loads and provides more precise control in applications requiring high power, such as in construction equipment and industrial machinery. The choice between these two types of cylinders often depends on the specific requirements of the job, including load capacity, speed, and operating environment.

The Role of Factories in Cylinder Production

Pneumatic and hydraulic cylinder factories play a crucial role in the supply chain of manufacturing operations. These factories are typically equipped with advanced technology and skilled personnel who work together to design, produce, and test these vital components.

1. Design and Engineering At the forefront of cylinder production are engineers and designers who develop cylinder specifications tailored to meet customer needs. Utilizing computer-aided design (CAD) software, they create prototypes and simulate performance under various conditions, ensuring that the final products are robust and reliable.

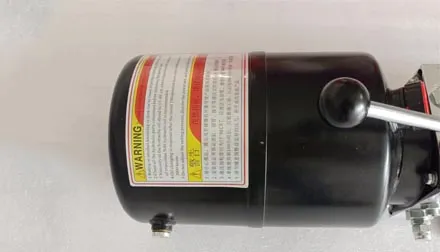

pneumatic hydraulic cylinder factories

2. Manufacturing Processes The manufacturing process of pneumatic and hydraulic cylinders involves several crucial steps, including machining, welding, and assembly. High-precision machining centers cut and shape materials, ensuring that the cylinder components fit together seamlessly. For hydraulic cylinders, welding is often required to join sections together securely, ensuring they can withstand high pressure.

3. Quality Control Factories adhere to strict quality control standards. Each cylinder undergoes rigorous testing to ensure it meets industry standards for performance and safety. Pressure tests, leak tests, and durability assessments are performed to guarantee that every cylinder can withstand the demands of its intended application.

4. Customization and Flexibility One of the significant advantages of specialized factories is their ability to offer customization. Clients from various industries can request specific sizes, materials, and features that suit their unique operational challenges. This flexibility fosters innovation, allowing businesses to integrate the most suitable cylinders into their systems.

The Future of Pneumatic and Hydraulic Cylinder Factories

As the demand for automation and efficient energy use continues to grow, pneumatic and hydraulic cylinder factories are adapting to meet emerging trends. The integration of smart technology into these systems is one of the most significant developments. Factories are increasingly incorporating IoT (Internet of Things) devices into their products, allowing for real-time monitoring and predictive maintenance. This not only enhances performance but also extends the lifespan of the cylinders.

Sustainability is another vital consideration. Manufacturers are investing in environmentally friendly practices and materials, focusing on reducing waste and energy consumption throughout the production process. This shift not only helps the planet but also appeals to eco-conscious consumers.

Conclusion

Pneumatic and hydraulic cylinder factories are essential players in the industrial ecosystem. By continuously innovating and adapting to market demands, these factories not only contribute to the efficiency and safety of countless applications but also play a pivotal role in shaping the future of manufacturing. As technology advances and industries evolve, the importance of high-quality, reliable cylinders will remain a cornerstone of modern machinery, ensuring that factories stay at the forefront of production excellence.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025