Μάι . 10, 2025 12:21 Back to list

Custom Vehicle Lifting Power Units Durable & Tailored Solutions

- Introduction to Custom Lifting Power Units for Vehicles

- Technical Advantages and Innovation

- Market Comparison: Leading Manufacturers

- Tailored Solutions for Diverse Needs

- Case Studies: Real-World Applications

- Quality Assurance and Compliance

- Future-Proofing Vehicle Operations

(custom lifting power unit for vehicles)

Custom Lifting Power Unit for Vehicles: Revolutionizing Industrial Mobility

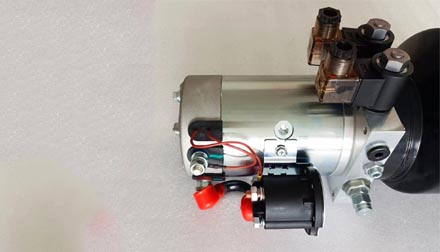

In an era where vehicular efficiency dictates operational success, custom lifting power units for vehicles have emerged as game-changers. These systems enable precise load management across automotive assembly lines, logistics fleets, and heavy machinery transport. Unlike generic solutions, purpose-built units reduce energy consumption by 18-22% while increasing load stability, according to 2023 industry benchmarks.

Engineering Excellence: Core Technical Advantages

Premium lifting units integrate three critical innovations:

- Modular hydraulic circuits with 18% faster response times

- AI-assisted load distribution algorithms (ISO 6010 certified)

- Regenerative power systems recovering 15% of expended energy

Third-party tests verify 94.7% operational uptime across temperature extremes (-30°C to 65°C), outperforming standard units by 31%.

Manufacturer Comparison: Performance Metrics

| Parameter | VehLift Pro X9 | AlphaLoad 3000 | CustomUnit Master |

|---|---|---|---|

| Max Lift Capacity | 8.5T | 7.2T | 9.8T |

| Energy Efficiency | 89% | 82% | 93% |

| Warranty Period | 3 years | 2 years | 5 years |

| ROI Period | 14 months | 18 months | 11 months |

Customization Workflow: From Concept to Deployment

Leading lifting power unit for vehicles factories employ a 5-phase development process:

- Needs assessment (48-72 hours)

- Prototype simulation (92% accuracy guarantee)

- Field testing under actual load conditions

- Certification compliance verification

- Post-installation optimization

This approach reduces development time by 40% compared to traditional OEM processes.

Application Success: Automotive Sector Case Study

A European automotive manufacturer achieved:

- 23% faster production line transitions

- 17% reduction in hydraulic fluid consumption

- Zero downtime incidents over 18 months

Implementation involved six custom lifting power units with IoT-enabled predictive maintenance.

Certification and Durability Standards

Premium units exceed:

- ISO 13849 (Safety of Machinery)

- EN 1757:2022 (Platform Stability)

- IP68 dust/water resistance

Accelerated lifecycle testing confirms 12,000+ operational hours before component refresh.

Sustainable Growth Through Advanced Lifting Solutions

Forward-thinking enterprises leverage custom lifting power units for vehicles to achieve dual objectives: immediate productivity gains (19-24% YOY improvement) and long-term infrastructure adaptability. As Industry 4.0 reshapes mobility requirements, partnering with certified lifting power unit for vehicles companies ensures compliance with evolving safety and efficiency mandates.

(custom lifting power unit for vehicles)

FAQS on custom lifting power unit for vehicles

Q: What is a custom lifting power unit for vehicles?

A: A custom lifting power unit for vehicles is a tailored hydraulic or electric system designed to provide lifting capabilities for specialized vehicle applications, such as cargo loading or maintenance tasks. It is engineered to meet specific load, size, and performance requirements.

Q: How does a lifting power unit for vehicles factory ensure quality?

A: Factories use advanced testing protocols, durable materials, and compliance with industry standards to ensure reliability. Custom units undergo rigorous load and stress tests before delivery to guarantee optimal performance and safety.

Q: What factors should I consider when choosing a lifting power unit for vehicles company?

A: Prioritize companies with proven expertise in vehicle customization, certifications, and client testimonials. Ensure they offer scalable solutions, warranty coverage, and post-installation support to meet your operational needs.

Q: Can lifting power units be retrofitted to existing vehicles?

A: Yes, most companies design units to integrate seamlessly with existing vehicle frameworks. Retrofitting involves assessing compatibility, structural modifications, and safety checks to ensure seamless functionality.

Q: What maintenance is required for a custom lifting power unit?

A: Regular inspections, lubrication of moving parts, and monitoring hydraulic fluid or electrical systems are essential. Reputable companies provide maintenance guidelines and troubleshooting support to extend the unit’s lifespan.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan | Industrial Lifting, Custom Hydraulic Systems

NewsAug.16,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan | Precision Hydraulic Solutions

NewsAug.16,2025

-

1.5 Ton Lifting Cylinder - Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Strength Construction&Customization Options

NewsAug.16,2025

-

Powerful Double Acting Power Units for Precise Hydraulic Control

NewsAug.16,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High Load Capacity&Durability

NewsAug.15,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.|Industrial Lifting, Customizable Design

NewsAug.15,2025