Ion . 29, 2025 04:11 Back to list

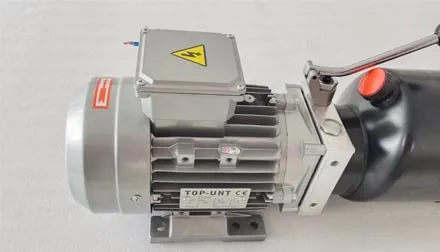

high quality balanced hydraulic cylinder

In the intricate world of industrial machinery and engineering, the quest for efficiency, reliability, and performance precision never ceases. Hydraulic systems, being the life blood of numerous mechanical operations, demand components that are not just functional but exceptional in quality. Among such pivotal components, hydraulic cylinders play a crucial role. A high-quality balanced hydraulic cylinder is not just an appendage; it is the heart of a robust hydraulic system, ensuring smooth operations, energy efficiency, and a long service life.

Authoritativeness in the field of hydraulic equipment is demonstrated through a manufacturer's adherence to international standards and rigorous testing protocols. Certifications from recognized bodies, such as the International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME), serve as benchmarks of quality and reliability. Companies that consistently comply with these standards assure end-users of a product's safety, efficiency, and performance—all vital aspects when opting for a hydraulic cylinder that can make or break industrial operations. Trust, the foundation of any transaction, is paramount when selecting a high-quality balanced hydraulic cylinder. Trustworthy manufacturers are transparent in their production processes and are often willing to customize solutions to meet specific client needs. This client-centric approach not only highlights the manufacturer’s commitment to quality but also fosters a sense of partnership, ensuring technical support and service even post-purchase. Testimonials and case studies from existing clients further buttress the manufacturer's credibility, offering potential buyers insights into real-world applications and performance of the cylinders. The decision to invest in high-quality balanced hydraulic cylinders goes beyond the act of purchase—it is an investment in the efficiency and reliability of your operation. The benefits extend to improved energy efficiency, reduced operational costs, and enhanced system longevity, making it a financially prudent choice in the long run. When considering an upgrade or maintenance of hydraulic systems, it is crucial to deliberate on these aspects, weighing the upfront costs against the accrued benefits over the equipment's lifecycle. In essence, a top-notch balanced hydraulic cylinder exemplifies the pinnacle of engineering excellence, innovation, and reliable performance. It is a testament to human ingenuity and the relentless pursuit of perfection in industrial mechanics. As industries evolve and the demands on hydraulic systems become more exacting, the role of these cylinders will continue to expand, offering solutions that promise not only to meet but to exceed operational expectations in every possible dimension.

Authoritativeness in the field of hydraulic equipment is demonstrated through a manufacturer's adherence to international standards and rigorous testing protocols. Certifications from recognized bodies, such as the International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME), serve as benchmarks of quality and reliability. Companies that consistently comply with these standards assure end-users of a product's safety, efficiency, and performance—all vital aspects when opting for a hydraulic cylinder that can make or break industrial operations. Trust, the foundation of any transaction, is paramount when selecting a high-quality balanced hydraulic cylinder. Trustworthy manufacturers are transparent in their production processes and are often willing to customize solutions to meet specific client needs. This client-centric approach not only highlights the manufacturer’s commitment to quality but also fosters a sense of partnership, ensuring technical support and service even post-purchase. Testimonials and case studies from existing clients further buttress the manufacturer's credibility, offering potential buyers insights into real-world applications and performance of the cylinders. The decision to invest in high-quality balanced hydraulic cylinders goes beyond the act of purchase—it is an investment in the efficiency and reliability of your operation. The benefits extend to improved energy efficiency, reduced operational costs, and enhanced system longevity, making it a financially prudent choice in the long run. When considering an upgrade or maintenance of hydraulic systems, it is crucial to deliberate on these aspects, weighing the upfront costs against the accrued benefits over the equipment's lifecycle. In essence, a top-notch balanced hydraulic cylinder exemplifies the pinnacle of engineering excellence, innovation, and reliable performance. It is a testament to human ingenuity and the relentless pursuit of perfection in industrial mechanics. As industries evolve and the demands on hydraulic systems become more exacting, the role of these cylinders will continue to expand, offering solutions that promise not only to meet but to exceed operational expectations in every possible dimension.

Latest news

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025