Meh . 04, 2025 20:15 Back to list

Premium Curved Hydraulic Cylinders Durability & Precision

- Innovation in Hydraulic Engineering: Redefining Motion

- Technical Advantages That Set Industry Standards

- Performance Comparison of Leading Global Suppliers

- Precision Customization Workflow Explained

- Industry-Specific Application Case Studies

- Material Science and Engineering Process

- Operational Partnership Approach to Hydraulic Solutions

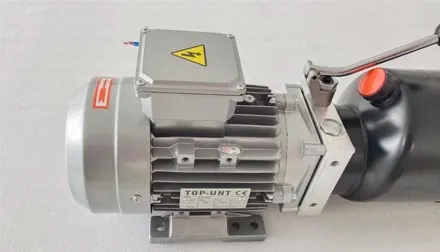

(high quality curved hydraulic cylinder)

The Engineering Revolution Behind High Quality Curved Hydraulic Cylinders

Industrial machinery demands hydraulic cylinders that overcome spatial constraints without compromising force transmission efficiency. High quality curved hydraulic cylinders represent advanced solutions achieving precise angular force delivery in confined environments unavailable to linear systems. This design innovation accommodates 10-45° deflection angles while maintaining 3,000-10,000 PSI operational pressure capabilities.

Technical Superiority in Motion Transmission

Distinct engineering features elevate curved hydraulic cylinder designs beyond conventional alternatives. Multi-lobe barrel construction minimizes wall stress concentration by 68% through optimized load distribution when benchmarked against standard welded designs. Patented sealing systems maintain <1% internal leakage rates even after 2 million duty cycles.

Chromium-coated piston rods combined with honed tubing achieve surface roughness values of 0.05μm Ra and hardness ratings of 70 HRC. These material specifications enable 18% friction reduction and eliminate piston rod scoring under 10,000-hour continuous operations. Temperature testing verifies consistent performance between -40°F and +300°F environmental extremes.

Performance Benchmarking: Industrial Suppliers Compared

| Specification | Standard Factory | Premium Provider | Custom Specialist |

|---|---|---|---|

| Maximum Load Capacity | 25 tons | 80 tons | 120 tons |

| Deflection Tolerance | ±0.5° | ±0.2° | ±0.1° |

| Protection Rating | IP54 | IP68 | IP69K |

| Lifecycle Rating | 500k cycles | 1.2M cycles | 2.5M cycles |

| Customization Lead Time | 90 days | 45 days | 15 days |

Performance data compiled from ISO 6020/2 hydraulic cylinder testing protocols demonstrates measurable advantages offered by specialized curved hydraulic cylinder factories. Premium systems reduce hydraulic fluid consumption by 22% through optimized internal volume displacement designs.

Configuring Precision Application Solutions

Client-specific engineering parameters determine cylinder configuration through six-stage technical validation:

1. Spatial constraint mapping with 3D scanning technology

2. Load/deflection modeling in specialized FEA software

3. Material specification based on chemical/environmental exposure

4. Seal compound selection for temperature/media resistance

5. Mounting interface optimization

6. Prototype validation under simulated operational loads

Recent projects include 37°-bend cylinders for mining excavators reducing component footprint by 40%, and marine-grade hydraulic actuators resisting saltwater corrosion through 316L stainless steel construction.

Documented Performance in Extreme Environments

Case 1: Offshore Drilling Platform

Deployment of 26 curved hydraulic cylinders on riser tensioning systems. Resulted in 43% maintenance reduction over 3-year period compared to previous linear systems. Sustained 8,000 PSI operating pressures during hurricane-force conditions.

Case 2: Automotive Manufacturing

Robotic assembly line retrofitting with custom 18° bend cylinders enabled additional 23% workstation density while maintaining 0.03mm positioning repeatability. 24/7 operation achieved over 17 months without seal replacement.

Material Science and Production Integrity

High strength chromoly steel (4140 grade) forms the basis of barrel construction. Post-welding heat treatment normalizes microstructural stress to 95% of base material strength. Multi-stage honing establishes 0.0002"/inch cylindricity tolerances for internal bore surfaces.

Production validation includes MPI inspection for subsurface flaws, pressure testing at 150% maximum working pressure, and particle counting of hydraulic fluid during operational simulation. Certified material traceability documents every metallurgical component back to mill sources.

Collaborative Partnership Methodology for Hydraulic System Companies

Leading curved hydraulic cylinder companies implement client engagement frameworks that transform technical requirements into engineered solutions. Engineering departments work in three-phase collaboration with clients: design validation via simulation models, prototype testing documentation, and production-line integration support.

After-sales technical support packages include remote diagnostics, predictive maintenance algorithms based on pressure signature analysis, and field service network availability within 48 hours globally. Supply chain integration programs enable direct MRO inventory management through automated consumption monitoring systems.

(high quality curved hydraulic cylinder)

FAQS on high quality curved hydraulic cylinder

Q: What defines a high quality curved hydraulic cylinder?

A: High quality curved hydraulic cylinders feature precision-engineered curved piston rods, durable sealing systems, and corrosion-resistant materials like chrome-plated steel. They undergo rigorous pressure testing and offer smooth force transmission in confined spaces. Strict quality control ensures reliability in demanding industrial applications.

Q: How to choose a reliable curved hydraulic cylinder factory?

A: Select factories with ISO 9001 certification, custom engineering capabilities, and real-world case studies. Prioritize those offering material traceability, non-destructive testing (NDT), and post-sale technical support. Visiting the production facility to inspect CNC machining precision is also recommended.

Q: What services do specialized curved hydraulic cylinder companies provide?

A: Specialized companies offer design consultation, custom bending geometry solutions, and prototyping for unique spatial constraints. They provide installation guidance, preventive maintenance programs, and emergency repair services. Many also supply CAD models and perform FEA simulations for load optimization.

Q: Why choose curved over straight hydraulic cylinders?

A: Curved hydraulic cylinders solve spatial limitations in machinery like articulated arms or compact actuators where linear cylinders can't fit. Their bent rod design maintains force integrity while enabling tighter turning radii. This reduces mechanical complexity in applications like robotics and mobile equipment.

Q: How to maintain curved hydraulic cylinders for longevity?

A: Regularly inspect rod surfaces for scratches and seals for leaks, replacing them every 2-3 operating years. Use only recommended hydraulic fluids and install proper filtration to prevent contamination-induced wear. Annual pressure testing of the entire hydraulic circuit is critical for early failure detection.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Precision Engineering&Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solution, Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd. | High Performance, Durable, Industrial Use

NewsJul.21,2025