Nov . 05, 2024 13:42 Back to list

mini electric hydraulic cylinder factories

Exploring Mini Electric Hydraulic Cylinder Factories Innovations in Automation

In recent years, the demand for advanced automation solutions has surged, driving a significant transformation across numerous industries. One of the key components at the forefront of this revolution is the mini electric hydraulic cylinder. These compact devices are becoming increasingly popular due to their versatility, efficiency, and effectiveness in various applications. This article will delve into the significance of mini electric hydraulic cylinder factories and their contribution to modern manufacturing.

What are Mini Electric Hydraulic Cylinders?

Mini electric hydraulic cylinders are a type of actuator that combines the principles of hydraulics with electric power. Unlike traditional hydraulic systems that rely on pumps and reservoirs, mini electric hydraulic cylinders use an electric motor to facilitate the movement of hydraulic fluid, enabling the generation of linear force in a more compact and efficient manner. Their design allows for precise control, which is essential in automation and robotics.

These cylinders are typically smaller than conventional hydraulic cylinders, making them ideal for applications with space constraints. Their lightweight yet durable construction ensures they can perform reliably in diverse environments, from manufacturing lines to intricate robotic assemblies.

The Role of Mini Electric Hydraulic Cylinder Factories

The factories that produce mini electric hydraulic cylinders play a pivotal role in the manufacturing ecosystem

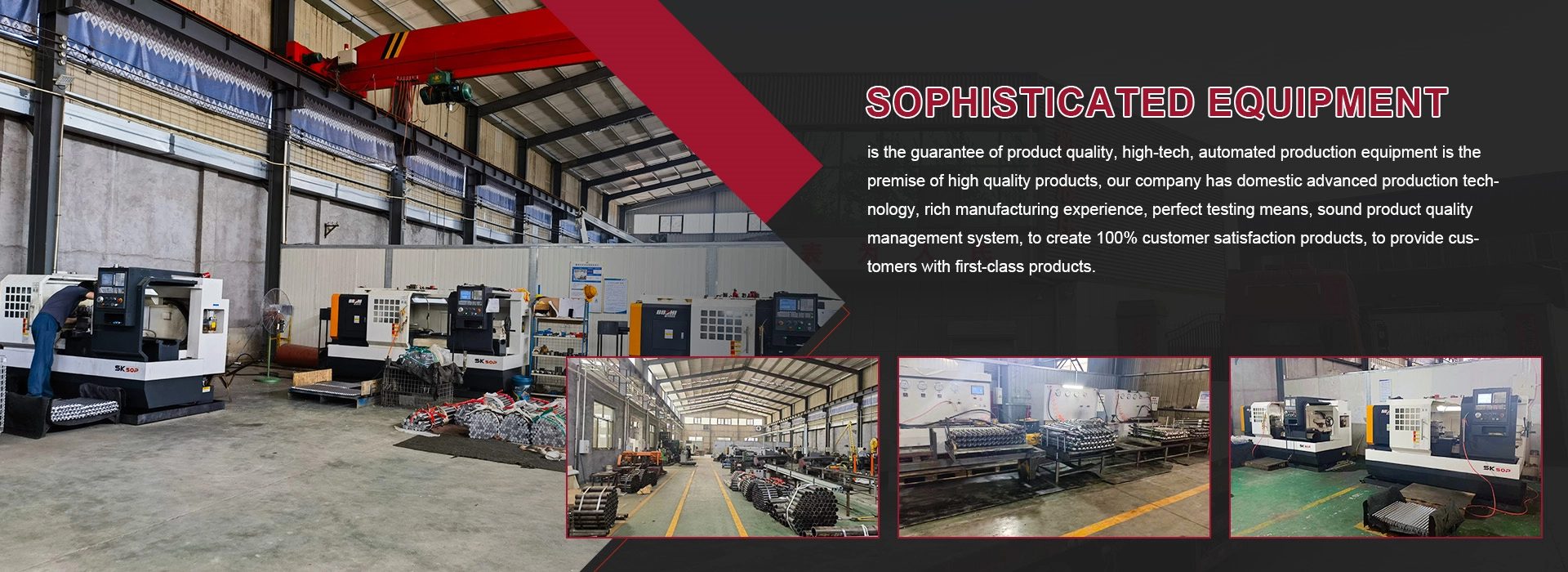

. These facilities are at the intersection of engineering innovation, quality assurance, and sustainable production practices. Here are several key aspects of these factories1. Innovation and Technology The factories are equipped with state-of-the-art machinery and technology, allowing them to produce highly engineered products that meet the evolving needs of industries ranging from automotive and aerospace to medical and energy. Research and development teams are constantly working on improvements in design and functionality, focusing on energy efficiency, performance enhancement, and reduced environmental impact.

2. Customization One of the standout features of mini electric hydraulic cylinder factories is their ability to customize products according to specific client requirements. Many industries have unique needs, and factories can modify their offerings in terms of size, pressure ratings, and control systems. This level of customization helps businesses optimize their operations and achieve greater efficiency.

mini electric hydraulic cylinder factories

3. Quality Control Maintaining high standards of quality is crucial in hydraulic system manufacturing. Mini electric hydraulic cylinder factories implement rigorous quality control measures throughout the production process, from the selection of raw materials to the final inspection of completed products. This ensures reliability and durability, ultimately leading to customer satisfaction and long-term partnerships.

4. Sustainability As the world increasingly prioritizes sustainability, mini electric hydraulic cylinder factories are also adopting eco-friendly practices. This includes reducing waste, using recyclable materials, and implementing energy-efficient manufacturing processes. By doing so, they contribute positively to the environment while meeting the demands of environmentally-conscious consumers and businesses.

5. Global Supply Chain Integration Many mini electric hydraulic cylinder factories are part of a larger global supply chain, allowing them to source materials and components from various regions. This integration ensures that production remains efficient and cost-effective while enabling them to respond quickly to market changes and customer demands.

Applications of Mini Electric Hydraulic Cylinders

The versatility of mini electric hydraulic cylinders makes them suitable for numerous applications

- Robotics These cylinders are frequently used in robotic arms and automated systems, providing precise movement for tasks such as assembly, welding, and packaging. - Automated Machinery In the manufacturing sector, they drive processes in machinery that require high force in a limited space. - Medical Devices Mini electric hydraulic cylinders are used in various medical applications, including surgical robots and rehabilitation equipment, where precision and control are paramount. - Aerospace In aerospace applications, they are used for actuation systems that require reliability and lightweight designs to optimize performance.

Conclusion

Mini electric hydraulic cylinder factories are essential contributors to the contemporary landscape of automation and manufacturing. Their commitment to innovation, customization, quality control, and sustainability ensures that they not only meet existing market demands but also pave the way for future advancements. As industries continue to evolve, these factories will remain at the heart of technological progress, providing solutions that enhance efficiency and effectiveness across a wide range of applications. The future of manufacturing is undoubtedly intertwined with the continued development and enhancement of mini electric hydraulic cylinders.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solution, Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd. | High Performance, Durable, Industrial Use

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan Hydraulic Machinery Co., Ltd.|Heavy-Duty Lifting Solutions&Precision Engineering

NewsJul.21,2025