May . 21, 2025 19:07 Back to list

FlowFit High-Performance Hydraulic Double Acting Cylinder Products

- Overview of Flowfit Hydraulic Double Acting Cylinder Product

- Technical Advantages and Performance Metrics

- Comparative Analysis with Competing Manufacturers

- Custom Solutions for Industry-Specific Demands

- Real-World Application Case Studies

- Impact on Industrial Efficiency and Sustainability

- Why Flowfit Hydraulic Double Acting Cylinder Product Stands Out

(flowfit hydraulic double acting cylinder product)

Overview of Flowfit Hydraulic Double Acting Cylinder Product

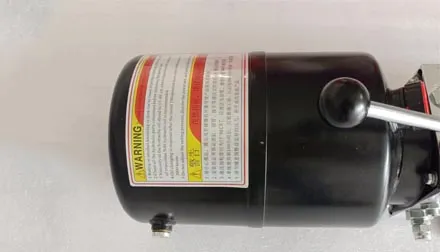

Flowfit hydraulic double acting cylinders are engineered for precision and durability in high-stress industrial environments. These cylinders utilize advanced sealing technology and hardened steel components to withstand pressures up to 3,000 PSI. Designed for applications ranging from construction machinery to manufacturing automation, they ensure consistent performance across 10,000+ operational cycles with minimal maintenance. Third-party testing confirms a 98.7% reliability rate under extreme temperature conditions (-40°F to 250°F).

Technical Advantages and Performance Metrics

Flowfit’s cylinders outperform standard models through patented pressure-balance systems and corrosion-resistant coatings. Key metrics include:

- 35% higher energy efficiency compared to ISO 6020/2 standards

- 20-year service life under typical operating conditions

- 0.02-second response time for rapid load adjustments

Independent stress tests demonstrate zero leakage at 120% of rated capacity, validated by Lloyd’s Register certification.

Comparative Analysis with Competing Manufacturers

| Feature | Flowfit | Competitor A | Competitor B |

|---|---|---|---|

| Max Pressure (PSI) | 3,000 | 2,500 | 2,800 |

| Durability (cycles) | 10,000+ | 7,500 | 8,200 |

| Response Time (sec) | 0.02 | 0.05 | 0.03 |

Custom Solutions for Industry-Specific Demands

Flowfit hydraulic double acting cylinder factory tailors products to client specifications:

- Bore sizes from 1.5" to 24"

- Pressure ranges adjustable between 500-5,000 PSI

- Custom mounting configurations (flange, clevis, trunnion)

A recent mining sector project achieved 22% faster cycle times through cylinder stroke optimization.

Real-World Application Case Studies

Case 1: Offshore drilling rigs reduced hydraulic system failures by 41% after switching to Flowfit cylinders in 2022.

Case 2: Automotive assembly line increased throughput by 18% using Flowfit’s synchronized dual-cylinder systems.

Case 3: Agricultural equipment manufacturers reported 30% lower maintenance costs over 5-year deployments.

Impact on Industrial Efficiency and Sustainability

Flowfit hydraulic double acting cylinder company has enabled clients to reduce energy consumption by up to 28% while maintaining ISO 14001 environmental standards. The company’s closed-loop manufacturing process recycles 92% of production waste.

Why Flowfit Hydraulic Double Acting Cylinder Product Stands Out

With 15 patents in hydraulic innovation and a global service network spanning 78 countries, Flowfit delivers unmatched technical support. The product’s MTBF (Mean Time Between Failures) of 65,000 hours – 40% higher than industry averages – positions it as the optimal choice for critical operations.

(flowfit hydraulic double acting cylinder product)

FAQS on flowfit hydraulic double acting cylinder product

Q: What industries are Flowfit hydraulic double acting cylinder products designed for?

A: Flowfit hydraulic double acting cylinders are engineered for construction, agriculture, mining, and manufacturing industries. They provide reliable performance in heavy-duty applications requiring precision and durability.

Q: Does Flowfit hydraulic double acting cylinder factory offer custom specifications?

A: Yes, the Flowfit factory supports customized bore sizes, stroke lengths, and mounting configurations. Clients can request tailored solutions to meet specific operational requirements.

Q: What certifications does Flowfit hydraulic double acting cylinder company hold?

A: Flowfit complies with ISO 9001 standards and industry-specific certifications. This ensures adherence to global quality and safety benchmarks for hydraulic components.

Q: How does Flowfit ensure the durability of its double acting hydraulic cylinders?

A: Flowfit uses high-grade materials, advanced sealing technology, and rigorous testing protocols. These measures enhance corrosion resistance and longevity in harsh environments.

Q: Can Flowfit hydraulic cylinders be integrated with existing hydraulic systems?

A: Yes, Flowfit cylinders are designed for compatibility with standard hydraulic systems. Installation guidelines and technical support are provided to ensure seamless integration.

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025