Oct . 31, 2024 22:17 Back to list

Custom Hydraulic Pump and Cylinder Solutions for All Your Pressing Needs

Custom Hydraulic Press Pump and Cylinder A Comprehensive Overview

Hydraulic systems have been pivotal in various industries, driving efficiency and precision in tasks ranging from manufacturing to construction. At the heart of these systems lies the hydraulic press pump and cylinder, which play crucial roles in converting and transmitting power through hydraulic fluid. Custom hydraulic press pumps and cylinders are increasingly becoming essential for organizations seeking tailored solutions to meet specific operational requirements.

A hydraulic press pump is responsible for generating the hydraulic pressure required to perform work, while the hydraulic cylinder translates that pressure into linear motion. When both components are designed to meet unique specifications, they can dramatically enhance the functionality and efficiency of hydraulic applications. Customization may include adjusting size, pressure ratings, flow rates, and materials used, all of which are essential factors that influence performance.

One of the foremost advantages of custom hydraulic press pumps and cylinders is their adaptability. Industries such as automotive, aerospace, metalworking, and recycling often have distinct requirements that off-the-shelf products can't fulfill. For instance, a manufacturing plant that deals with heavy materials may require a hydraulic cylinder capable of exerting a higher force than standard models. By opting for a custom solution, companies can ensure that their equipment meets precise load specifications, ultimately improving workflow and minimizing the risk of breakdowns.

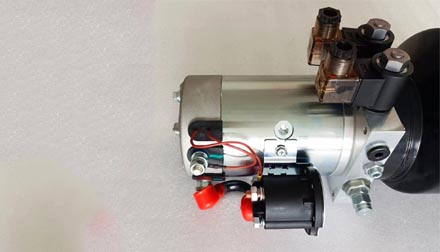

custom hydraulic press pump and cylinder

Additionally, custom hydraulic systems can improve safety. When components are specifically designed for a particular application, it reduces the chances of failure during operation. This is particularly important in high-stakes environments where equipment malfunctions may lead to accidents or injuries. Customization allows for the inclusion of safety features tailored to the operational environment, providing an added layer of protection for workers.

Moreover, efficiency is a critical factor in any hydraulic system, and utilizing custom hydraulic press pumps and cylinders can substantially enhance it. These tailored solutions are engineered to minimize energy losses within the system, resulting in lower operational costs. This is particularly relevant for businesses keen on reducing their carbon footprint and meeting increasingly stringent sustainability targets.

The design and manufacturing of custom hydraulic press pumps and cylinders require expertise in fluid dynamics and engineering principles. Collaborating with specialized manufacturers who understand the intricacies of hydraulic systems is crucial for achieving optimal results. They can offer insights into materials, design modifications, and integration with existing systems, ensuring that the final product functions seamlessly within the broader hydraulic architecture.

In conclusion, investing in custom hydraulic press pumps and cylinders offers significant advantages over off-the-shelf alternatives. From enhanced adaptability and safety to improved efficiency and reduced operational costs, tailored solutions are designed to meet the specific needs of diverse industries. As hydraulic technology continues to evolve, the demand for customized solutions capable of tackling unique challenges will only increase, making the role of custom hydraulic systems pivotal in driving industrial success. Organizations that recognize the value of customization are likely to experience enhanced productivity and a competitive edge in their respective markets.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Precision Engineering&Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solution, Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd. | High Performance, Durable, Industrial Use

NewsJul.21,2025