Nov . 08, 2024 00:53 Back to list

Premium Hydraulic Cylinder Components for Enhanced Performance and Durability

The Importance of High-Quality Hydraulic Cylinder Parts

Hydraulic systems are integral to various industries, ranging from manufacturing to construction and beyond. At the heart of these systems lies the hydraulic cylinder, a device that converts hydraulic energy into mechanical motion. To ensure the efficient and reliable performance of hydraulic cylinders, it is crucial to use high-quality hydraulic cylinder parts. This article explores the significance of these components, the benefits they provide, and the factors to consider when selecting them.

Understanding Hydraulic Cylinders

Before delving into the importance of high-quality parts, it is essential to understand what hydraulic cylinders are and how they function. A hydraulic cylinder consists of a cylinder barrel, piston, piston rod, seals, and other components. When pressurized hydraulic fluid enters the cylinder, it acts on the piston, creating linear motion. This motion can be harnessed for lifting, pushing, or pulling heavy loads, making hydraulic cylinders vital in various applications, including cranes, forklifts, and industrial machines.

The Significance of High-Quality Parts

1. Performance and Efficiency High-quality hydraulic cylinder parts are designed to withstand high pressures and extreme conditions. They provide reliable performance by ensuring consistent fluid flow and minimizing leakage. This efficiency translates into better overall system performance, leading to higher productivity and reduced downtime.

2. Longevity and Durability Investing in high-quality components means that they are manufactured to meet strict standards and specifications. Durable materials and precise engineering reduce wear and tear over time, extending the lifespan of hydraulic cylinders. This longevity translates into lower replacement and maintenance costs, offering long-term savings.

3. Safety Considerations Hydraulic systems operate under high pressure, making safety a paramount concern. Poor-quality parts can lead to catastrophic failures, resulting in equipment damage and, more importantly, risking worker safety. High-quality hydraulic cylinder parts are subject to rigorous testing to ensure they can withstand the pressures and forces they will encounter, mitigating the risk of accidents.

4. Better Sealing Performance Seals are critical components in hydraulic systems. They prevent fluid leakage and contamination, which are vital for maintaining system efficiency. High-quality sealing materials can withstand varying temperatures, pressures, and fluid compositions, ensuring optimal functionality. Poor seals can lead to leaks, reduced system efficiency, and increased costs.

5. Compatibility and Customization High-quality manufacturers often offer a variety of components tailored to different needs and applications. This means that businesses can find parts that fit their systems perfectly, ensuring compatibility and optimal performance. Additionally, many manufacturers can provide custom solutions, allowing for enhanced functionality based on specific requirements.

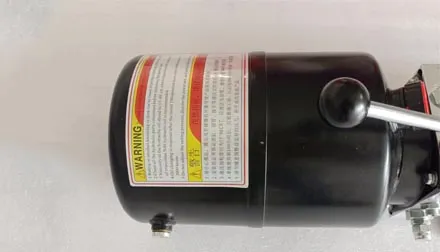

high quality hydraulic cylinder parts

Factors to Consider When Selecting Parts

When sourcing hydraulic cylinder parts, several factors must be weighed to ensure high-quality choices

1. Material Quality Opt for parts made from high-grade materials, such as high-carbon steel or corrosion-resistant alloys, to ensure robustness and durability.

2. Manufacturing Standards Choose parts manufactured in compliance with international standards, such as ISO or ANSI. This compliance ensures the components meet safety, performance, and reliability benchmarks.

3. Supplier Reputation Work with reputable suppliers known for their commitment to quality. Research customer reviews, industry ratings, and certifications to gauge reliability.

4. Technical Support A good supplier should provide excellent customer service, including technical support for installation and maintenance. This support can be invaluable in troubleshooting issues or ensuring optimal setup.

5. Cost vs. Quality While it might be tempting to opt for cheaper alternatives, investing in high-quality parts often pays off in terms of reliability, longevity, and overall operational efficiency.

Conclusion

In conclusion, the importance of high-quality hydraulic cylinder parts cannot be overstated. They play a significant role in ensuring the efficiency, safety, and longevity of hydraulic systems. By investing in quality components and considering key factors during selection, businesses can enhance their operational capabilities and minimize the risks associated with hydraulic systems. Ultimately, the performance of these systems relies heavily on the quality of their parts, making it imperative for industries to prioritize quality in their hydraulic applications.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025