nov. . 21, 2024 14:27 Back to list

elevator hydraulic cylinder factories

The Significance of Hydraulic Cylinders in Elevator Manufacturing

Hydraulic cylinders are a crucial component in the operation of elevators, particularly in hydraulic lift systems. Unlike traction elevators that rely on cables and pulleys, hydraulic elevators utilize a hydraulic pump, fluid, and cylinder to lift and lower the cab. This system is not only efficient but also offers unique advantages that make it a popular choice in low to mid-rise buildings. In this article, we will explore the role of hydraulic cylinders in the elevator industry, the manufacturing process, and the factors to consider when selecting a hydraulic cylinder factory.

Understanding Hydraulic Systems in Elevators

Hydraulic elevators operate based on the principles of fluid mechanics. When the elevator's control system sends a signal, hydraulic fluid is pumped into the cylinder, creating pressure that pushes a piston upward, thus raising the elevator cab. To descend, the fluid is released, and the weight of the cab forces the piston down. This simple yet effective mechanism allows for smooth and reliable vertical transportation.

Manufacturing Hydraulic Cylinders

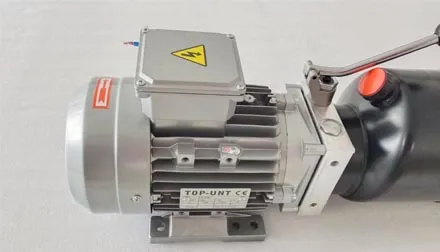

The production of hydraulic cylinders involves precise engineering and rigorous quality control to ensure safety and reliability in elevator operations. Factories specializing in hydraulic cylinders incorporate advanced technologies and techniques to manufacture durable, high-performance cylinders.

1. Material Selection The process begins with selecting the right materials that can withstand high pressure and corrosion. Common materials include steel and specialized alloys, which offer resilience and strength.

2. Machining After material selection, the cylinders are machined to exact specifications. CNC (Computer Numerical Control) machines are often utilized to achieve precise dimensions and tolerances. This step is critical, as even minor discrepancies can lead to failures in the hydraulic system.

3. Surface Treatment To enhance durability, the cylinders undergo surface treatments such as polishing, coating, or plating. These treatments help prevent wear and tear and protect against corrosive elements.

4. Assembly The components of the hydraulic cylinder, including the piston, seals, and connectors, are carefully assembled. Quality control measures are implemented at each stage to ensure that the assembly meets the required safety standards.

elevator hydraulic cylinder factories

5. Testing Once assembled, hydraulic cylinders undergo rigorous testing to evaluate their performance under varying pressures. Leak tests, pressure tests, and functional tests are performed to guarantee that the cylinders will operate safely and effectively in an elevator system.

Choosing a Reliable Hydraulic Cylinder Factory

When selecting a hydraulic cylinder factory for elevator manufacturing, several factors should be considered

1. Quality Certifications Look for manufacturers that hold industry certifications, such as ISO 9001, which indicates a commitment to quality management systems.

2. Experience and Reputation A factory with a proven track record in producing hydraulic cylinders for elevators will have a better understanding of industry standards and customer expectations.

3. Customization Options Depending on specific elevator designs and requirements, customization may be necessary. A good manufacturer should offer tailored solutions to meet diverse applications.

4. Aftermarket Support Consider the level of support offered post-purchase. A reputable manufacturer will provide technical assistance, warranty services, and maintenance recommendations.

5. Innovation and Technology Factories that invest in the latest technology will likely produce more efficient and reliable hydraulic cylinders. Staying updated with advancements can improve performance and reduce maintenance costs.

Conclusion

Hydraulic cylinders are fundamental to the functionality of hydraulic elevators, providing a reliable method for vertical transportation. The manufacturing process demands high standards of engineering, and the right factory can significantly impact the performance and safety of elevator systems. By understanding the importance of hydraulic cylinders and making informed decisions when selecting a manufacturer, stakeholders in the elevator industry can enhance their products and services, ensuring efficient and safe transportation for all building occupants.

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025