ታኅሣ . 29, 2024 17:00 Back to list

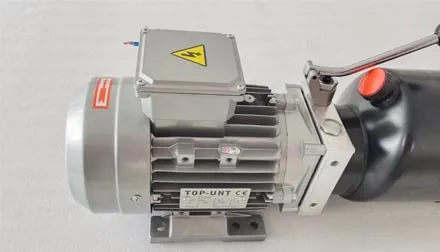

hydraulic locking cylinder products

Understanding Hydraulic Locking Cylinders

Hydraulic locking cylinders are essential components in various industrial applications where safety and control are paramount. These cylinders serve as vital actuators that harness the power of hydraulic fluid under pressure to create movement and hold objects securely in place. In this article, we will explore the functionality, advantages, applications, and maintenance of hydraulic locking cylinders.

What Are Hydraulic Locking Cylinders?

Hydraulic locking cylinders operate utilizing the principles of hydraulics—specifically the application of fluid pressure to generate force. These cylinders consist of a piston and a cylinder housing, with hydraulic fluid (oil) filling the space between them. The primary feature that distinguishes a hydraulic locking cylinder from standard hydraulic cylinders is its ability to maintain its position without continuous hydraulic pressure. This is achieved through a locking mechanism, which can be mechanical or hydraulic in design.

When the hydraulic fluid is pumped into the cylinder, the piston moves, and the object attached to the piston is lifted or pushed. Once the desired position is achieved, the locking mechanism engages to prevent any unintentional movement, effectively locking the piston in place. This feature is critical in applications where safety is a concern, such as in construction equipment, manufacturing machinery, and heavy-load lifting systems.

Advantages of Hydraulic Locking Cylinders

Hydraulic locking cylinders offer several key benefits

1. Enhanced Safety The ability to lock in position means that hydraulic systems can hold heavy loads securely, reducing the risk of accidents or equipment failures.

2. Energy Efficiency Once the desired position is reached, these cylinders do not require continuous fluid pressure to maintain their position, conserving energy and reducing operational costs.

3. Reliable Performance Designed to withstand high pressures and environmental conditions, hydraulic locking cylinders are known for their robustness and longevity.

4. Precision Control They provide precise control over movement, allowing operators to perform complex tasks with accuracy.

5. Versatility These cylinders can be adapted for various applications across multiple industries, including construction, automotive, aerospace, and manufacturing.

Applications of Hydraulic Locking Cylinders

Hydraulic locking cylinders are employed in numerous industries and applications

hydraulic locking cylinder products

- Construction Equipment In machinery like excavators and cranes, hydraulic locking cylinders are used to hold heavy loads, preventing unintentional drops during operations.

- Manufacturing They are used in automated systems for assembly lines, where precise positioning and holding of components are required.

- Aerospace Locking cylinders are critical in landing gear systems, where stability and safety during landing and takeoff are paramount.

- Automotive In vehicle lifts and hydraulic jacks, locking cylinders ensure the vehicles remain securely elevated during maintenance or repairs.

- Marine Applications Hydraulic locking cylinders are utilized in various marine equipment, ensuring that components are held in place under harsh conditions.

Maintenance of Hydraulic Locking Cylinders

Proper maintenance of hydraulic locking cylinders is crucial for optimal performance and longevity

1. Regular Inspection Frequent checks for signs of wear, leaks, or corrosion can prevent minor issues from becoming significant problems.

2. Fluid Quality Using the correct hydraulic fluid and maintaining its cleanliness helps ensure efficient operation and prevents damage.

3. Seals and Gaskets Inspect seals and gaskets regularly to avoid leaks and maintain pressure within the system.

4. Lubrication Ensure that any moving parts are adequately lubricated to reduce friction and wear.

5. Follow Manufacturer Guidelines Adhering to the manufacturer’s maintenance recommendations will help ensure the reliability and efficiency of the hydraulic locking cylinder.

Conclusion

Hydraulic locking cylinders are indispensable in today’s industrial landscape, merging safety with efficiency and control. As industries continue to evolve and technology advances, the importance of reliable hydraulic systems, particularly those equipped with locking cylinder capabilities, remains undeniable. Understanding their functionality, benefits, applications, and maintenance will go a long way in maximizing their potential in various operations.

-

OTC Hydraulic Cylinder Manufacturer - High-Quality Industrial Cylinders Supplier

NewsJul.06,2025

-

Best China Hydraulic Lift Cylinder Price Factory Direct Hydraulic Lift Cylinder Price Company

NewsJul.06,2025

-

Top Flip Plow Hydraulic Cylinder Manufacturers Custom Solutions Available

NewsJul.05,2025

-

Custom Cascade Hydraulic Cylinder Manufacturer & Supplier - Precision Engineered Solutions

NewsJul.05,2025

-

3x8 Hydraulic Cylinder Product - High Quality OEM Hydraulic Solutions from Trusted Manufacturer

NewsJul.04,2025

-

High-Quality Hydraulic Cylinder of Sanitation Truck Reliable Manufacturers & Factory Price

NewsJul.04,2025